The Role of CAD/CAM Software in Streamlining CNC Operations

Share Post

The Role of CAD/CAM Software in Streamlining CNC Operations

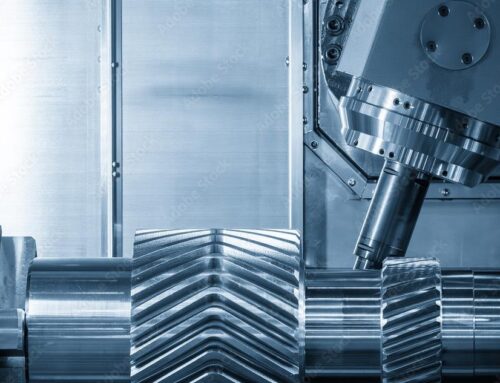

CNC (Computer Numerical Control) machining is one of the best ways to create precise parts. But without the right software, the process can be slow and lead to mistakes. This is where CAD (Computer-Aided Design) and CAM Computer Aided Manufacturing (CAM software) come in. These tools help engineers design parts, control CNC machines, and speed up the production process.

With CAD/CAM software, companies can make high-quality parts with extreme accuracy, reduce material waste, and avoid errors. These programs help businesses work faster, create consistent products, and save money. As CNC machining keeps evolving, CAD/CAM software is becoming even more advanced, making manufacturing smoother and more efficient.

What is CAD/CAM Software?

CAD and CAM software work together to bring digital designs to life by providing precise instructions for CNC machines to cut, drill, and shape materials. CAD software is used to create detailed 2D and 3D models of parts before they are manufactured. Engineers rely on these programs to design every curve, hole, and feature, ensuring that each part meets the required specifications.

How CAD/CAM Software Improves CNC Machining

This software makes it easy to adjust designs and create complex shapes that would be difficult to draw by hand. Once the design is complete, CAM software takes over. It generates the tool paths and machine instructions needed to guide CNC machines through the cutting and shaping process.

This automation reduces the need for manual work, improves efficiency, and ensures high precision. By using CAD and CAM software together, manufacturers can streamline the CNC machining process, making it faster, more accurate, and more cost-effective.

CNC machining requires extreme precision, and CAD/CAM software seamlessly integrates to help improve every step of the process.

With 3D CAD software, designers can quickly create part models, while CAM software converts these designs into machine instructions in just minutes. This speeds up production and allows manufacturers to bring products to market faster. Because designs are created digitally, the risk of human error is much lower compared to manual programming, ensuring greater accuracy in every part.

CAM software also helps optimize material use by calculating the most efficient way to cut, reducing waste and lowering costs. CNC machines guided by CAD/CAM software produce identical parts every time, which is especially important in industries like aerospace and medicine, where precision is critical.

Many CAM programs include simulation tools that allow engineers to preview the machining process before production begins. This helps prevent mistakes, improves efficiency, and ensures that parts are made correctly the first time. Additionally, CAM software selects the best cutting paths, tools, and speeds, making machining faster while extending the life of cutting tools. By using CAD/CAM software, manufacturers can create high-quality parts with accuracy, consistency, and minimal waste.

The Role of CAD Software in Designing Complex Parts

Some industries require parts with very detailed designs and tight tolerances. CAD software makes designing these parts much easier.

- Creating Complex Geometries: CAD software allows engineers to design intricate shapes and features that would be difficult to create manually.

- 3D Visuals for Better Designs: Engineers can view 3D models of their parts before manufacturing begins. This helps them spot design issues early and avoid unnecessary revisions.

- Testing and Simulation: Some CAD programs include testing tools that show how a part will perform in real-world conditions, helping to improve durability and reduce the need for physical prototypes.

- Easily Modified Designs: Engineers can quickly adjust designs using CAD software. If a part needs a small change, it can be modified digitally without starting from scratch.

- Standardized Models for Mass Production: CAD software helps manufacturers create standardized models that can be used across multiple production runs. This is especially useful for automotive and electronics manufacturing processes.

How CAM Software Optimizes CNC Machining

Once a part is designed in CAD, it must be manufactured efficiently. CAM software converts CAD models into precise CNC machine instructions, ensuring accuracy and speed.

CAM software creates tool paths that guide CNC machines on how to cut, drill, and finish a part. It selects the best cutting tools based on the material and part complexity, improving efficiency. Before machining starts, engineers can use CAM software to simulate the process, helping to catch and fix errors early.

By optimizing cutting paths and automating setup, CAM software reduces downtime and speeds up production. It also simplifies programming for advanced CNC machines, like 5-axis systems, making complex parts easier to create.

Integrating CAD/CAM software helps manufacturers produce high-quality parts faster, lower costs, and streamline the entire machining process.

Industries That Use CAD/CAM Software

Many industries rely on CAD/CAM software to speed up manufacturing, reduce mistakes, and improve accuracy. This technology helps create detailed designs and ensures CNC machines produce high-quality parts with minimal waste.

In aerospace, lightweight yet strong parts like turbine blades and aircraft frames must be made with extreme precision to ensure safety. CAD/CAM software helps engineers design and manufacture these complex components while minimizing material waste.

The automotive industry uses CAD/CAM to design and build custom engine parts, gears, and frames. Every piece must fit perfectly for a vehicle to function properly. This software also allows manufacturers to test and refine designs before production, preventing costly errors.

In the medical field, CNC machining is used for prosthetics, implants, and surgical tools. These devices must meet strict safety standards, and CAD/CAM software ensures they are made with precision. It even allows for custom prosthetics tailored to individual patients.

Electronics manufacturing depends on CAD/CAM for small, highly detailed parts like circuit boards and connectors. Accurate designs ensure these components function correctly in various devices.

Jewelry makers and engravers use CAD/CAM software to create intricate, custom designs with precision. It allows for experimenting with patterns and lettering while making quick adjustments without starting from scratch.

Across these industries, CAD/CAM software makes production faster, more accurate, and more cost-effective.

The Future of CAD/CAM in CNC Machining

Technology is improving quickly, and CAD/CAM software is becoming even more powerful. Here are some of the trends shaping the future of CNC machining:

- Artificial Intelligence (AI) in CAD/CAM: AI-powered software can analyze designs, suggest better ways to machine parts, and fix problems before production starts. This helps reduce waste and improve part quality.

- Cloud-Based CAD/CAM: Engineers can now work on CAD/CAM designs from anywhere in the world using cloud-based software. This makes teamwork easier, reduces errors, and speeds up production.

- More Automation: Future CAM software will require less manual input, making CNC machining faster and easier for all types of manufacturers.

- Smart Factories: Some manufacturers are connecting CAD/CAM software with automated factories. This allows machines to adjust settings in real-time, increasing production speed and reducing downtime.

- Virtual Reality (VR) and Augmented Reality (AR) in Design: Some CAD software now allows engineers to view and edit 3D models in virtual reality. This helps designers spot errors and make improvements before machining begins.

Challenges and How to Solve Them

Even though CAD/CAM software is useful, companies face challenges when using it. One major issue is the high cost of software, hardware upgrades, and employee training. However, these expenses pay off over time by reducing mistakes, cutting material waste, and improving efficiency.

Learning the software can also be difficult, as some programs are complex. Providing online training, tutorials, and user-friendly tools can help employees adapt more quickly.

Compatibility issues may arise when older CNC machines don’t work with newer software. Regular updates and proper machine setup can solve this problem. Cybersecurity risks are another concern, especially with cloud-based CAD/CAM storage. Using secure servers, encryption, and multi-step authentication helps protect sensitive designs.

By addressing these challenges, companies can fully benefit from CAD/CAM technology while keeping operations smooth and secure.

The Growing Importance of CAD/CAM Software in CNC Machining

CAD/CAM software is essential for modern CNC machining. It helps companies design complex parts, reduce waste, and improve efficiency. As technology keeps improving, CAD/CAM software will continue to play a key role in manufacturing. With AI, automation, and smart factories, businesses will be able to create even more advanced products with incredible accuracy and speed.