In-House CNC Service:

Repairs, Retrofits and Upgrades

Why Choose Our Repairs, Retrofits and Upgrades?

In-House CNC Service:

Repairs, Retrofits and Upgrades

Why Choose Our Repairs, Retrofits and Upgrades?

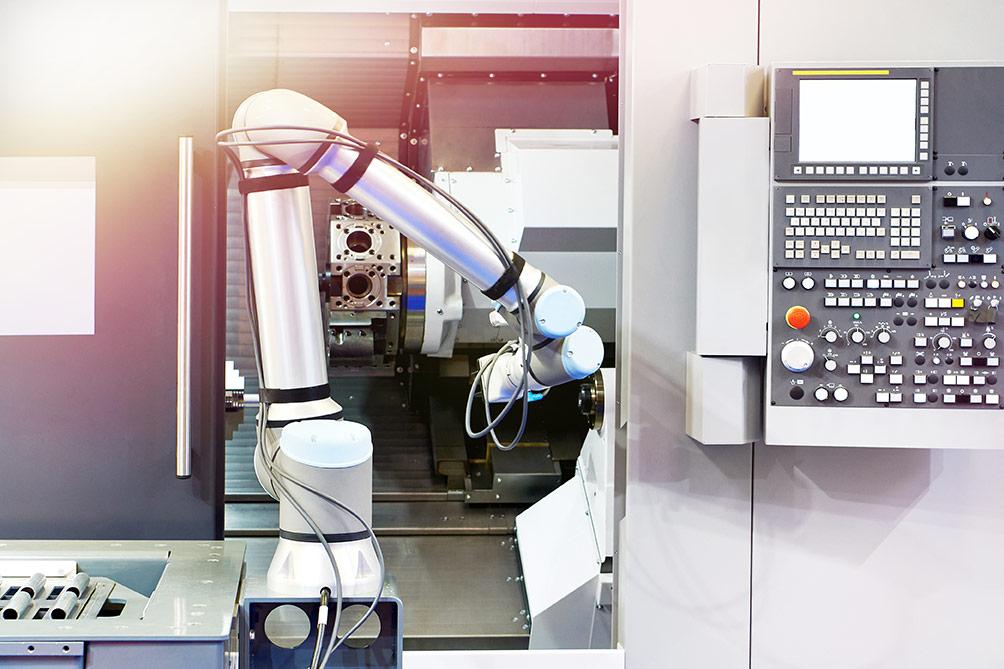

Enhance Performance with CNC Repairs, Retrofits, and Upgrades

CNC machines naturally experience wear over time, leading to performance issues, inefficiencies, and potential downtime. While repairs restore function, retrofits and upgrades enhance capabilities, allowing you to improve accuracy, speed, and productivity without replacing your equipment.

At In-House CNC, we specialize in comprehensive repair, retrofit, and upgrade services, helping you extend machine life, optimize performance, and stay ahead of industry demands. Whether you need urgent repairs, modernized controls, or upgraded components, we ensure your CNC machines operate at peak efficiency.

Key Benefits of CNC Repairs, Retrofits, and Upgrades

Enhanced Machine Performance and Precision

Upgrading outdated components and retrofitting modern technology improves machine speed, accuracy, and reliability, ensuring higher-quality production with reduced waste.

Cost-Effective Alternative to New Equipment

Rather than investing in expensive replacements, retrofits and upgrades allow you to maximize the value of your existing machines. Repairs keep equipment operational without the high costs of purchasing new machinery.

Minimized Downtime and Increased Efficiency

Timely repairs and proactive upgrades reduce unexpected breakdowns and optimize machine output, keeping your production line running smoothly with fewer interruptions.

Sustainable and Environmentally Friendly Solutions

Extending the life of your CNC machines through upgrades and retrofits reduces waste and energy consumption, aligning with sustainable business practices while lowering operational costs.

At In-House CNC, we help businesses boost productivity, reduce costs, and improve machine longevity with expert repair, retrofit, and upgrade solutions.

Common CNC Repair and Maintenance Services

Routine Maintenance to Prevent Failures – Regular inspections, cleaning, lubrication, and system checks help identify potential issues early, preventing costly breakdowns and ensuring consistent machine performance.

Component Replacements for Long-Term Reliability – Worn parts such as spindles, bearings, belts, and ball screws can lead to reduced accuracy and inefficiencies. Replacing these components restores precision and extends machine life.

Calibration for Accuracy and Consistency – Regular calibration ensures proper machine alignment and positioning, improving repeatability and reducing material waste during production.

Emergency Repairs to Minimize Downtime – Unexpected failures can halt operations. Our team provides rapid-response troubleshooting and repairs, ensuring your machines return to full operation as quickly as possible.

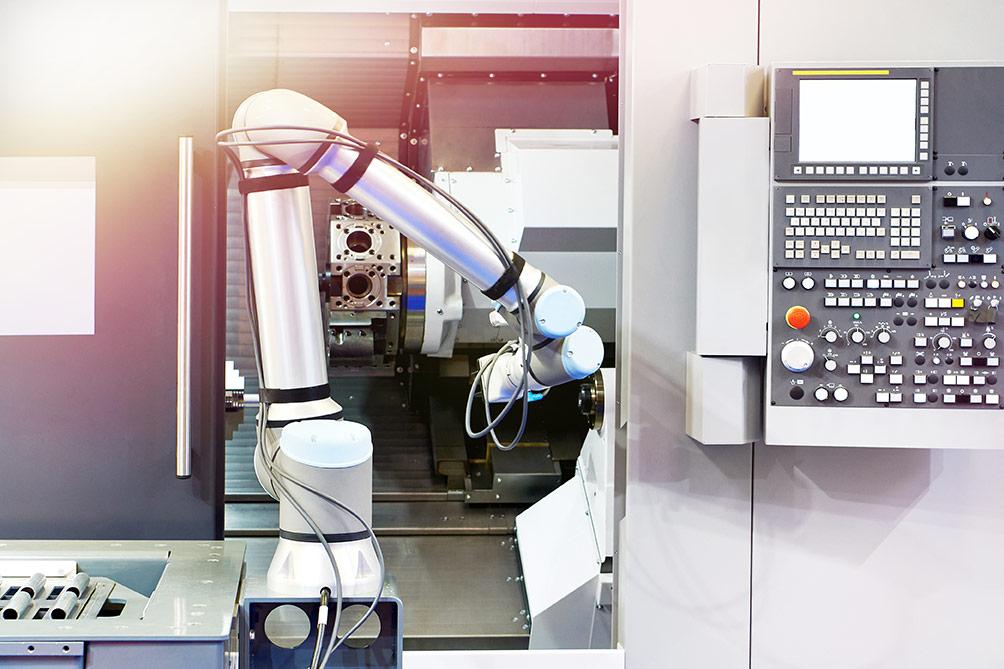

The Value of CNC Retrofits

Increase Productivity Without Replacing Equipment

Retrofits allow you to modernize aging CNC machines by integrating advanced controls, automation, and upgraded components, improving efficiency and output without investing in new equipment.

Cost-Effective Performance Enhancements

Upgrading key machine elements, such as servo motors, drive systems, or control interfaces, enhances speed, precision, and automation capabilities, delivering modern performance at a fraction of the cost of a new machine.

Tailored Solutions for Your Specific Needs

Retrofits can be customized to fit your production requirements, whether you need increased spindle speeds, upgraded software, or improved energy efficiency to meet evolving industry demands.

How Upgrades Take Your Equipment Further

Boost Efficiency and Throughput

Upgrading essential components—such as motors, drives, or software—can significantly increase production speeds and reduce cycle times, maximizing output and profitability.

Enhance Accuracy and Product Quality

Modern upgrade options offer improved motion control, tighter tolerances, and enhanced sensor technology, ensuring precise, high-quality products with less rework or waste.

Support Larger Workloads and Complex Tasks

By bolstering machine capabilities—like expanded axes, additional tooling, or advanced automation—you can take on more demanding projects and handle greater production volumes. Investing in upgrades allows you to future-proof your CNC equipment, adapting to new market demands and staying one step ahead of the competition.

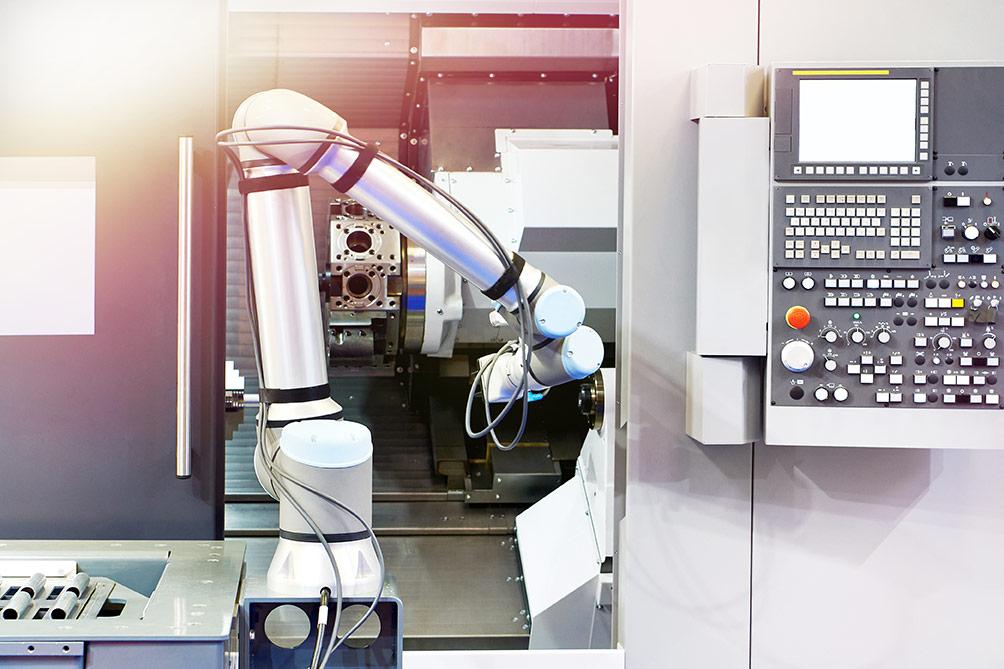

Partner with In-House CNC for Repairs, Retrofits, and Upgrades

At In-House CNC, we specialize in machine repairs, retrofits, and performance upgrades to help you maximize productivity, extend equipment life, and reduce downtime. Our expert technicians provide customized solutions to restore, enhance, and modernize your CNC machines.

Whether you need urgent repairs, precision calibration, control system retrofits, or efficiency-boosting upgrades, we deliver high-quality service tailored to your specific operational needs. Contact us today to discuss how our repair, retrofit, and upgrade services can optimize your CNC equipment.

Extend Machine Life and Enhance Performance with CNC Repairs, Retrofits, and Upgrades

Outdated or failing equipment can slow production, increase costs, and limit efficiency. Proactive repairs, retrofits, and upgrades ensure your CNC machines operate at peak performance, reduce downtime, and stay competitive.

At In-House CNC, we help you restore, modernize, and optimize your equipment with expert repair and upgrade services. Don’t wait for inefficiencies to impact your bottom line—upgrade your CNC machines today.