In-House CNC Service:

Linear Motion Bearing Replacements

Why Choose Our Linear Motion Bearing Replacements?

In-House CNC Service:

Linear Motion Bearing Replacements

Why Choose Our Linear Motion Bearing Replacements?

Unleash Peak CNC Performance with Linear Motion Bearings

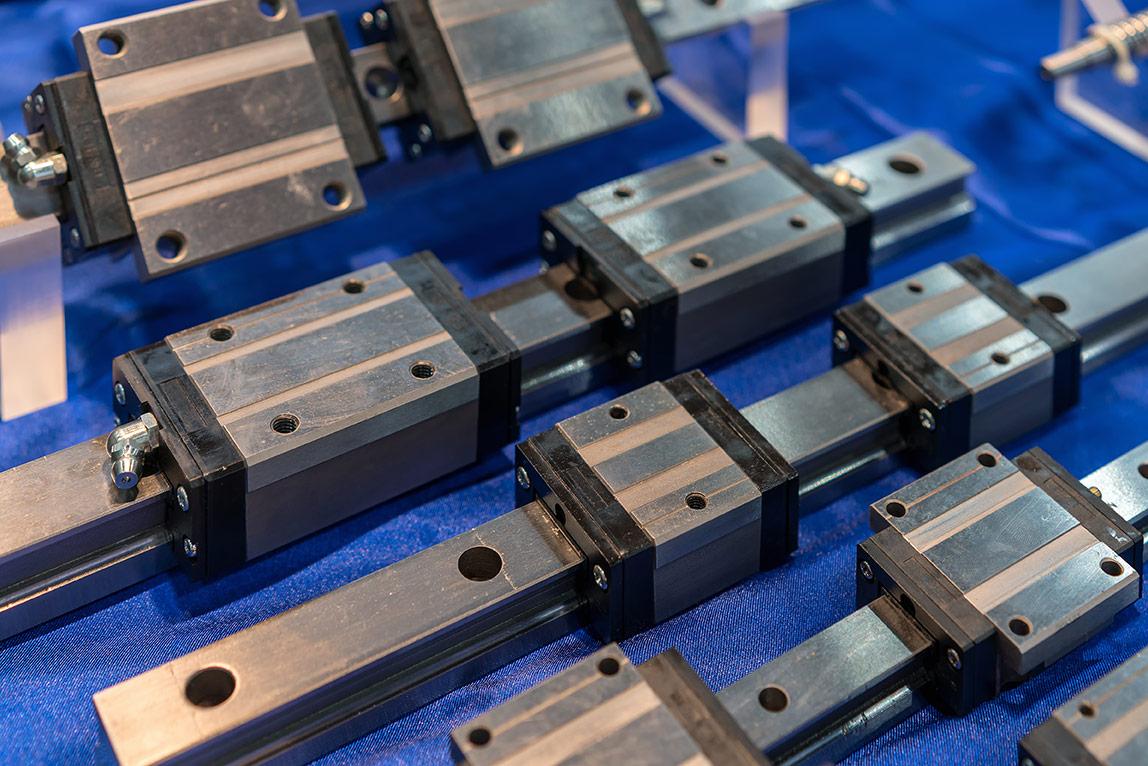

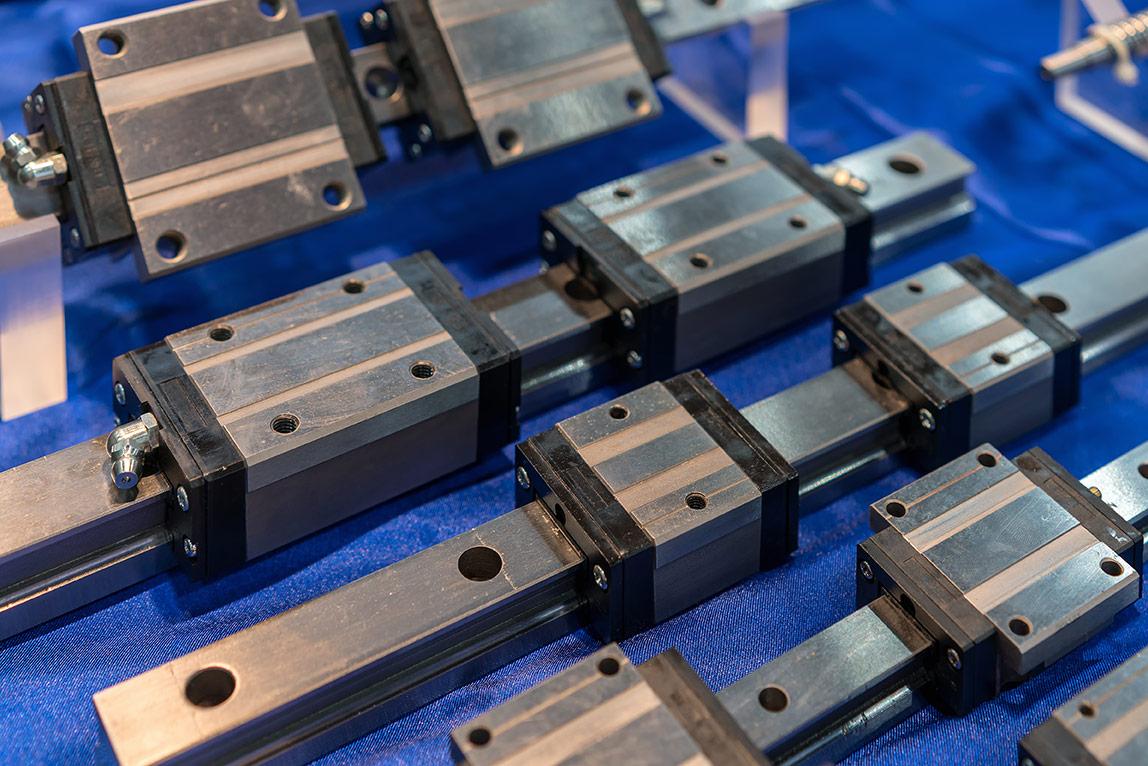

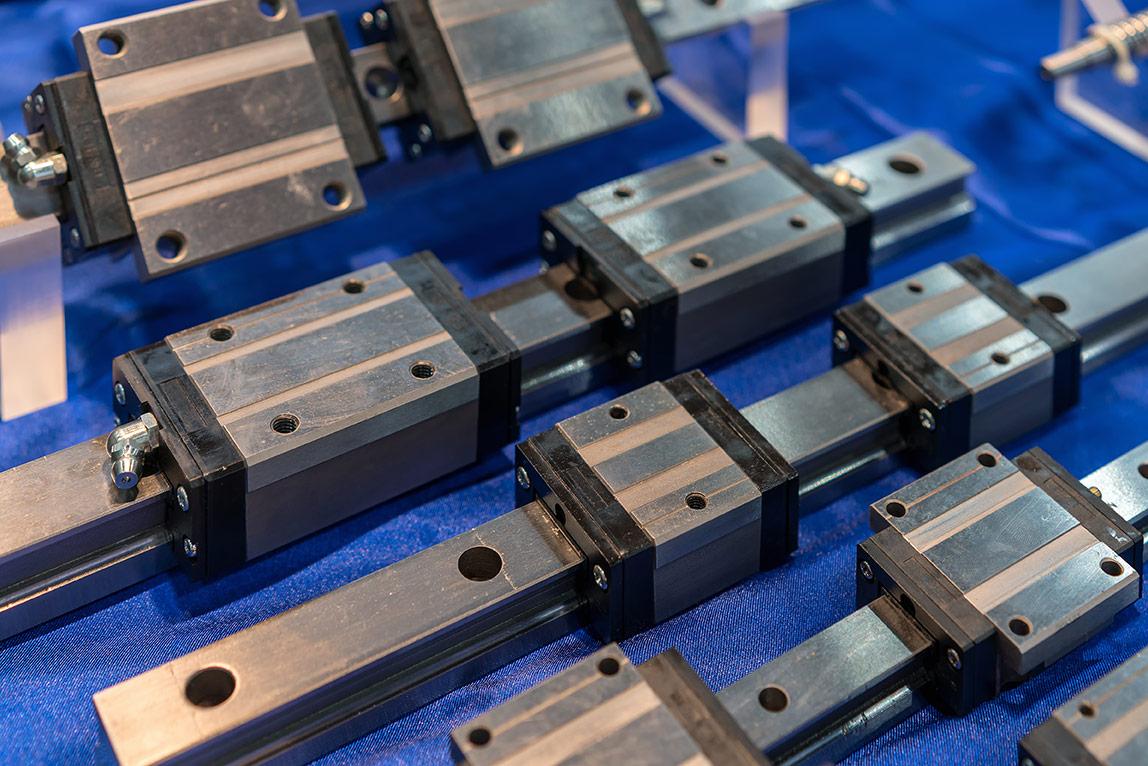

Linear motion bearings are essential components in CNC machines and other precision equipment, ensuring smooth, frictionless movement along a straight path. Without them, machine parts would grind against each other, leading to wear, inefficiencies, and costly breakdowns.

At In-House CNC, we provide high-quality linear motion bearings designed to enhance machine performance, increase durability, and maintain accuracy. Whether you need replacements, expert installation, or maintenance support, our solutions help keep your CNC machines running at peak efficiency.

Key Features of Our Linear Motion Bearing Solutions

Smooth, Precise Motion for CNC Machines

Linear motion bearings play a critical role in ensuring frictionless, straight-line movement within CNC machines. By reducing resistance between moving parts, they help maintain precision, efficiency, and machine longevity.

Types of Linear Motion Bearings

Our linear motion bearings are built using high-quality materials, such as stainless steel and engineered composites, to withstand heavy loads, high-speed applications, and harsh environments. This ensures long-term durability and consistent performance.

Optimized for Efficiency and Cost Savings

Properly installed and maintained bearings reduce wear and tear, minimize energy consumption, and extend the life of your CNC equipment. By choosing the right bearings for your machine, you can enhance operational efficiency and lower maintenance costs over time.

At In-House CNC, we offer expert solutions, installation services, and ongoing support to ensure your linear motion bearings provide maximum performance and reliability.

Types of Linear Motion Bearings

- Linear Ball Bearings – Designed for high-speed applications, linear ball bearings use precision-engineered ball bearings to minimize friction. They provide smooth, accurate movement, making them ideal for CNC machines requiring fast, precise motion.

- Linear Slides – Linear slides are built to handle heavy loads while maintaining stable, controlled motion along a linear path. These bearings are commonly used in manufacturing, automation, and industrial applications that demand reliable, long-term performance.

- Stainless Steel Bearings – For environments exposed to moisture, chemicals, or extreme temperatures, stainless steel bearings offer exceptional resistance to corrosion and wear. These durable bearings ensure consistent performance and longevity even in demanding conditions.

Each type of linear motion bearing provides unique advantages, and selecting the right one is crucial to maintaining optimal machine function and efficiency.

Key Benefits of Quality Linear Motion Bearings

Reduced Wear and Extended Machine Life

By minimizing friction, high-quality linear motion bearings help prevent excessive wear on machine components, significantly extending the lifespan of your CNC equipment.

Increased Efficiency and Precision

Smooth, controlled motion ensures accurate positioning, reducing errors and improving overall machining performance. This results in higher productivity and less wasted material.

Cost-Effective and Low Maintenance

Investing in durable, high-performance bearings reduces the need for frequent replacements and lowers long-term maintenance costs. With proper lubrication and upkeep, they help keep your CNC machines running efficiently with minimal downtime.

Choosing the right bearings enhances both the performance and reliability of your machines, making them a valuable investment for any precision-driven operation.

How to Install and Maintain Linear Motion Bearings

Proper Installation for Optimal Performance

Following manufacturer guidelines is crucial when installing linear motion bearings. Proper alignment and secure mounting ensure smooth movement, reduced friction, and long-term reliability in CNC machines.

Proper Installation for Optimal Performance

Routine visual and performance checks help identify early signs of wear, misalignment, or contamination. Addressing issues promptly prevents costly repairs and unexpected downtime.

Proper Installation for Optimal Performance

Using the correct lubricant reduces friction, minimizes heat buildup, and extends the lifespan of bearings. Regular lubrication ensures consistent, high-precision performance over time.

By following these installation and maintenance best practices, you can maximize the efficiency and longevity of your linear motion bearings, keeping your CNC machines operating at peak performance.

Partner with In-House CNC for Linear Motion Bearing Solutions

At In-House CNC, we provide high-quality linear motion bearings along with expert installation, maintenance, and replacement services to ensure your CNC machines operate at maximum efficiency. With our industry expertise and precision solutions, we help you select the right bearings for your specific needs, improving machine performance and longevity.

Whether you need new bearings, expert installation, or routine maintenance, our team is ready to keep your equipment running smoothly. Contact us today to discuss your linear motion bearing needs and optimize your CNC machine’s performance.

Ensure Smooth CNC Performance with Linear Motion Bearings

Friction and misalignment can lead to machine inefficiencies, premature wear, and costly downtime. High-quality linear motion bearings are essential for precise, reliable movement in CNC machines, keeping your operations running smoothly and efficiently.

At In-House CNC, we offer expert solutions for linear motion bearing selection, installation, and maintenance, ensuring your equipment performs at peak efficiency. Don’t let worn bearings slow you down—optimize your CNC machine’s motion with expert support today.