How to Keep a New Manual Lathe in Top Condition

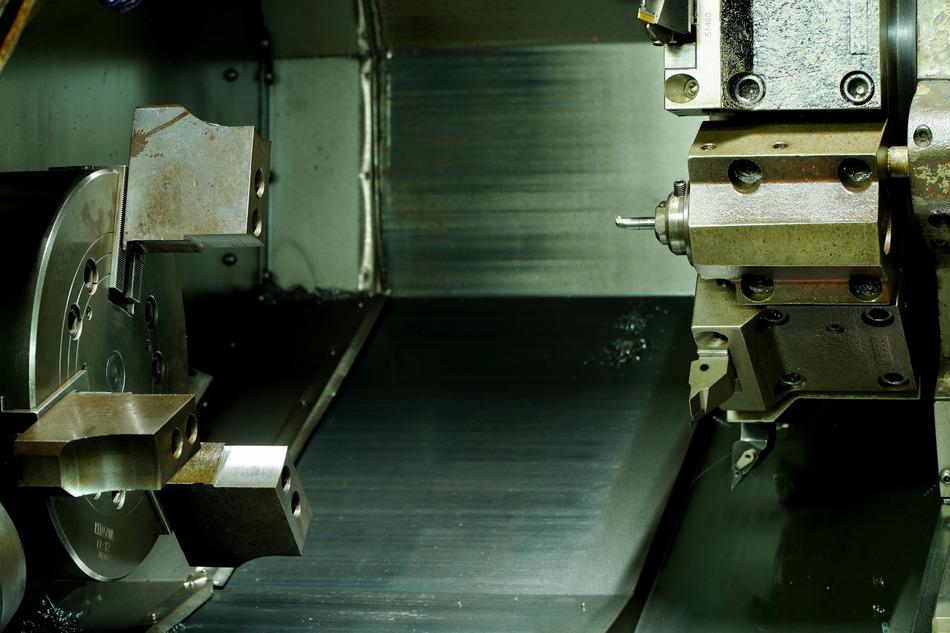

Sharp cutting tools are essential to keeping your lathe running smoothly. Whether you’re using a manual lathe or a CNC machine, dull or worn parts can cause more problems than you might expect. They don’t just lower the quality of your finished pieces—they also make your machine work harder, which leads to faster wear and more frequent repairs.

This can increase your downtime, delay orders, and raise your overall production costs. That’s why it’s so important to know when it’s time to replace your lathe parts. Staying ahead of tool wear helps you avoid bigger problems and maintain consistent results.

It’s also helpful to know where to buy high-quality replacements that match your machine’s specs. Having the right parts on hand can save you valuable time and reduce disruptions to your workflow.

When to Replace Sharp Lathe Parts

Dull or Rounded Cutting Edges

If your tools aren’t slicing cleanly, it’s time to inspect the edge. Rounded or dulled tips can cause rough finishes, tool chatter, and poor chip control. Even if the tool looks fine, a loss of precision during cutting could mean the edge is worn.

Chipped or Cracked Inserts

Look closely at carbide inserts or high-speed steel tips. Even a small chip can throw off accuracy or increase cutting pressure. Cracks will only get worse—replace chipped or damaged tools right away.

Burn Marks or Discoloration

Heat damage is a red flag. If the tool is showing dark blue or brown areas, it’s been running too hot. This can weaken the tool and affect surface finish, so swap it out before it damages your part or spindle.

Excess Vibration

A tool that’s past its prime can cause chatter or vibration during cuts. That vibration doesn’t just ruin the surface—it also puts stress on your lathe, collets, and spindle bearings.

Inconsistent Finish or Tolerance Issues

If your parts aren’t matching your specs or surface finish starts to suffer, your cutting tools might be the cause. Don’t waste time dialing in offsets when a fresh tool could solve the problem.

Where to Buy Replacement Lathe Parts

Industrial Suppliers

Big names like MSC, Grainger, and Travers Tool offer a wide range of lathe tools, inserts, and holders. They carry trusted brands and can usually ship fast. Great for standard parts and quick replacements.

OEM Dealers

If your lathe is from a major brand like Haas, Okuma, or Mazak, buying direct from the OEM ensures proper fit and tool spec. It’s often the best option for specialty holders or internal components.

Specialty Tool Distributors

Shops doing niche work—like gunsmithing or aerospace machining—may need custom tooling. Distributors like Harvey Tool, Kennametal, or Iscar offer application-specific tools that standard catalogs don’t carry.

Online Marketplaces

Amazon and eBay have become go-to options for budget-conscious shops. You can find deals on inserts, holders, and accessories—but quality varies. Always check seller ratings and reviews.

Stay Sharp: How to Keep Your Lathe Running

Sharp tools mean clean parts, longer machine life, and smoother runs. Pay attention to the signs of wear, replace tools before they become a problem, and keep a trusted supplier list handy.

📞 Need help finding the right replacement parts? Contact us today at (951) 540-4820. We can help you source, inspect, and maintain your lathe tooling for optimal performance.