Lathe Live Tooling Holders: Setup & Maintenance

Share Post

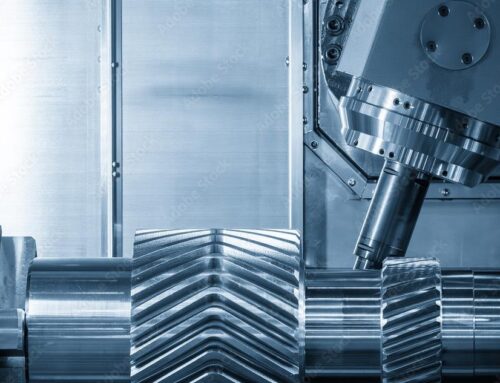

Lathe Live Tooling Holders: Setup & Maintenance

Live tooling holders are a key part of modern CNC lathes. They allow you to do milling, drilling, and tapping right on the lathe—without removing the part. That saves time, reduces handling, and speeds up production. If you run or maintain CNC machines, knowing how to set up and care for live tooling holders will help you get more out of your equipment.

What Are Lathe Live Tooling Holders?

Live tooling holders let you use spinning tools on a CNC lathe. This means your lathe can do some of the same work as a milling machine—all in one setup. These holders are powered by the machine’s motor or a built-in drive, allowing tools to rotate as needed. They’re perfect for jobs that need cross-holes, slots, or off-center features. Instead of moving the part to a mill, live tooling lets you complete everything in a single cycle.

How to Set Up Lathe Live Tooling Holders

Check Compatibility

Make sure the holder fits your CNC lathe’s turret, drive system, and control software.

Clean Surfaces

Wipe down the turret and holder before installation. Any dirt or debris can throw off alignment.

Use the Right Torque

Tighten mounting bolts to the torque spec listed by the manufacturer. This helps avoid vibration or damage.

Align the Holder

Use a test bar or dial indicator to confirm everything is aligned before starting up. Misalignment can cause wobbling.

Test at Low Speed

Before going into full production, run the spindle slowly to check for noise or shaking. Make sure the tool spins true.

Maintenance Tips

Lubricate as Needed

Follow the manufacturer’s instructions for grease or oil type and how often to apply it.

Inspect Seals and Bearing

Worn seals let coolant in, and bad bearings cause poor performance. Replace these if you see leaks or hear grinding.

Check for Runout

Use a dial indicator to check for tool wobble. High runout hurts part accuracy and wears out tools faster.

Test at Low Speed

Clogged coolant lines can overheat your tooling. Keep lines clear and filters clean.

Store Properly

When not using the holders, store them in a dry, protected place. Moisture and impact can shorten their lifespan.

Gain Your Confidence In Live Tooling Holders

Live tooling holders give your CNC lathe more flexibility by combining turning and milling in one setup. With proper setup and routine care, these holders can improve your part quality, reduce tool wear, and cut downtime.

📞 Need help with setup or maintenance? Contact In-House CNC Today at (951) 540-4820. We’ll help you get the most from your live tooling system.