How a CNC Spindle Kit Can Improve Your Machine

Share Post

How a CNC Spindle Kit Can Improve Your Machine

Your CNC machine is only as reliable as the spindle powering it. Whether you’re working on aerospace-grade components or custom firearm parts, the spindle is at the core of your setup. It must operate with precision, speed, and consistency. But over time, even the most robust spindle systems begin to degrade—especially if they’re not built for the demands of your current workload.

That’s where a CNC spindle kit comes in.

These upgrade kits are packed with everything you need to restore or enhance spindle performance. They help your machines run smoother, stay cooler, and perform better, even during long production cycles.

In this blog, we’ll cover what’s typically included in a CNC spindle kit, the benefits of upgrading, and how to know when it’s the right time for your shop to make the switch.

What Is a CNC Spindle Kit?

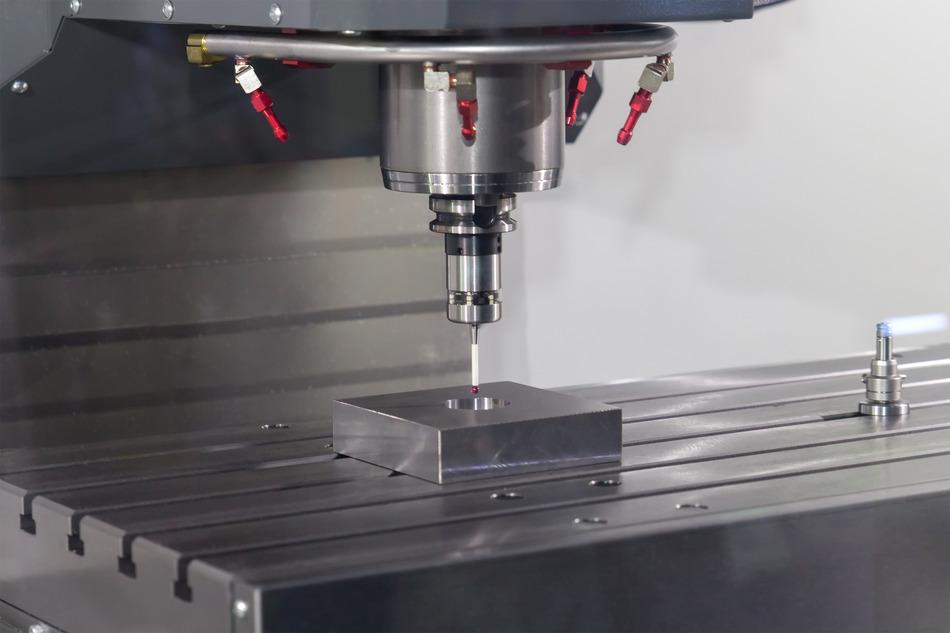

A CNC spindle kit is a pre-packaged set of parts that lets you rebuild, replace, or upgrade the spindle assembly in your CNC machine. The goal is to either bring your spindle back to like-new condition or improve its speed, torque, or durability for more advanced machining processes.

Spindle kits vary depending on your machine type, brand, and cutting requirements, but most include everything needed to restore full spindle function. Whether you’re using a CNC router, vertical mill, or precision lathe, the spindle is what powers your cutting tool—and its performance affects every part of the machining process.

The spindle assembly typically consists of the spindle motor, bearings, housing, drawbar, cooling system connections, and drive mechanisms. These parts take a lot of wear, especially under heavy use or with advanced materials. Over time, heat, friction, and misalignment can cause your spindle to lose accuracy, increase vibration, or fail entirely.

Installing a new CNC spindle kit replaces those worn parts with factory-matched or upgraded components—restoring smooth operation and precise control. More advanced kits may also include improved speed control features, high-precision bearings, or built-in temperature sensors to help monitor performance in real time.

If your shop depends on reliable, high-precision CNC machining, a quality spindle kit can help you get the most out of your equipment while extending its lifespan.

Key Components of a CNC Spindle Kit

Though spindle kits vary by manufacturer and machine, most contain essential parts designed to restore alignment, reduce heat buildup, and improve tool engagement. A standard CNC spindle kit will often include:

- Spindle Motor: The motor drives the spindle’s rotation and delivers the torque needed for cutting. High-speed kits may include brushless motors or VFD (Variable Frequency Drive) options for better spindle control.

- Precision Bearings: These are critical for smooth spindle rotation. High-performance kits often use angular contact or ceramic bearings to reduce friction, support high speeds, and extend lifespan.

- Spindle Housing & Mounting Hardware: This component keeps everything aligned. Precision-machined housings reduce vibration and ensure the internal components are seated properly to avoid premature wear.

- Drawbar & Collet System: These parts hold your cutting tools in place. Some kits include upgraded drawbars or tool-holding systems to ensure a tighter grip, minimizing the risk of tool slip during demanding operations.

- Cooling System Connections: Whether you’re using air- or water-cooled spindles, the kit may include new seals, fittings, or hoses. Effective cooling helps prevent overheating and supports extended run times without performance drops.

Each of these components plays a role in maintaining high-quality spindle operations and improving the overall health of your CNC machine.

Benefits of Upgrading to a CNC Spindle Kit

If your machine is aging or showing signs of spindle degradation, upgrading to a new spindle kit can deliver noticeable improvements in just about every aspect of machine performance. Here’s how:

1. Enhanced Speed Control

Modern spindle kits are designed with smoother, more stable RPM control in mind. If your old spindle hesitates during speed changes or bogs down during complex machining, a newer motor and controller can smooth out those transitions. That means better results during detailed cuts—especially in jobs that require high precision, like mold-making or custom prototype machining.

2. Better Heat Management

Excess heat is a major cause of spindle damage. It can lead to lubricant breakdown, warped components, and internal stress that shortens spindle life. Upgraded spindle kits often come with improved cooling features, such as water-cooled jackets, upgraded seals, or high-efficiency airflow systems. These features help dissipate heat during long runs and keep your spindle operating within safe temperature ranges.

3. Extended Spindle Life

Upgrading with a spindle kit helps prevent small issues from becoming costly repairs. By replacing worn bearings, collets, and other high-wear parts, you reduce vibration, lower tool wear, and maintain precision longer. This doesn’t just help your spindle—it protects your tooling and improves your overall machining workflow.

Spindle kits are more than just a repair—they’re an investment in consistent machine performance and fewer production disruptions.

When to Consider a CNC Spindle Kit Upgrade

You don’t need to wait for a breakdown to justify a spindle kit upgrade. Recognizing early warning signs can help you avoid downtime and maintain productivity. Here are a few indicators that it might be time:

Signs of Tool Wear

Are your cutting tools wearing out faster than usual? If you’re using proper feeds and speeds but still seeing poor chip control or rapid tool dulling, your spindle could be the culprit. Excess runout or imbalanced rotation increases tool stress—and a new kit can fix that.

Performance Lag

If your machine seems sluggish or is having trouble maintaining speed during demanding cycles, it may be a sign your spindle motor is underpowered or your drive system is outdated. New spindle kits often include upgraded motors and components that restore full cutting power.

Runout or Vibration

Excessive vibration is one of the most common indicators of a failing spindle. If you hear odd noises, see poor surface finishes, or notice movement in the tool path, there’s likely too much runout. A well-balanced spindle kit helps re-center the spindle and smooth out those irregularities—boosting both part quality and machine safety.

How CNC Spindle Kits Improve Real-World Performance

Installing a spindle kit isn’t just about improving specs—it can make a real difference on the shop floor.

Precision Aluminum Milling

An aerospace shop was struggling with tool wear and rough finishes during high-speed aluminum milling. Their old spindle couldn’t handle the heat or maintain speed. After upgrading to a water-cooled spindle kit with ceramic bearings, tool life jumped by 35%, and cycle times dropped by 20%. Cuts were smoother, and rework almost disappeared.

Gunsmithing Upgrades

A custom rifle shop had trouble with concentricity when threading barrels. Their standard spindle couldn’t hold alignment at low speeds. Switching to a high-torque spindle kit fixed the issue. Results were cleaner, tolerances stayed tight, and vibration was drastically reduced—even on long runs.

Spindle Kit Maintenance: Keep It Running Strong

A spindle kit boosts performance—but only if you take care of it.

Lubrication

Grease or oil your spindle as recommended. This keeps bearings healthy and prevents overheating. Skipping this step shortens the life of your kit.

Cooling

Water-cooled kits need clean coolant and strong flow. Air-cooled systems need clear fans and vents. Check these regularly to avoid overheating.

Regular Checks

Keep an eye (and ear) out for odd noises or vibration. Check surface finishes for signs of runout. Early detection keeps your machine cutting clean and accurate.

Choosing the Right Spindle Kit

Not every spindle kit fits every machine. Check your CNC’s speed range, torque requirements, and cooling system before buying. Think about what materials you machine and how often you run production.

If you cut aluminum fast, go for a high-speed kit. If you work with hard steel, you’ll want torque and stability. Also, make sure the kit includes clear instructions and support—so you’re not left guessing during setup.

Where to Buy Spindle Kits

Get your spindle kits from trusted vendors. For general needs, try:

- MSC Industrial

- Grainger

- Motion Industries

For precision jobs or specialty machines:

- NSK America

- IBAG North America

- Spindle Repair Services

Check for compatibility with your machine before buying. Look for good return policies, support options, and warranties.

Enhance Your Machining Efficiency: Upgrade Smart with CNC Kits

A CNC spindle kit can take your machine’s performance to the next level. You’ll get better part quality, less downtime, and longer tool life—all from one upgrade.

📞 Ready to boost performance? Contact In-House CNC at (951) 540-4820 to find the right spindle kit for your machine. We’ll help you upgrade with confidence.