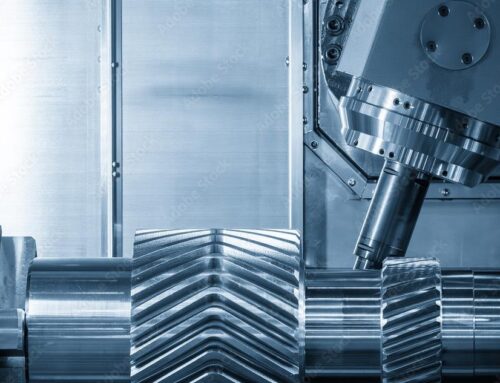

Best Metal Lathe Cutting Tools for Precision Work

Share Post

Best Metal Lathe Cutting Tools for Precision Work

When you’re cutting metal on a lathe, being accurate is very important. Whether you’re making a large number of parts or working on small, detailed pieces, the cutting tool you use makes a big difference. The right tool will help you get a smooth finish, reduce mistakes, and keep your parts consistent.

How To Choose?

Choosing the best metal lathe cutting tools isn’t just about buying the most expensive option. It’s about picking the tool that works best for your material, your job, and your machine.

Shops that need to make very exact parts count on tools that don’t shake, wear out quickly, or cause bad surface finishes. A tool that works well helps you save time, reduce waste, and make parts that meet your standards. In this guide, we’ll go over the most common types of lathe tools, and how they help improve your work.

What Makes The Best Metal Lathe Cutting Tools?

A good lathe tool needs to be sharp, strong, and right for the material you’re cutting. It should also work well with your machine’s speed and feed settings. But there’s more to it than that. The shape of the tool, how it handles heat, and how long it lasts all affect how well it performs.

Carbide Inserts: Fast and Reliable

Indexable carbide inserts are one of the most common tools used in machine shops. They’re small, replaceable cutting tips that fit into a tool holder. These inserts are strong, last a long time, and can be swapped out easily—so you don’t have to reset the whole tool when one wears down.

They’re great for cutting materials like steel, cast iron, and harder metals. If you work with different materials, you can get inserts with special coatings like TiN (Titanium Nitride) or TiAlN (Titanium Aluminum Nitride). These coatings help the tool last longer by handling heat better.

The shape of the insert matters too. Some are better for rough cuts, while others are made for smooth finishing work. Choosing the right one helps your parts come out clean and accurate.

High-Speed Steel (HSS): Great for Custom Work

High-speed steel tools don’t last as long as carbide, but they’re still very useful—especially if you need a special shape. These tools are easy to grind and sharpen in your shop, which makes them perfect for small jobs, detailed work, or soft materials like aluminum and brass.

HSS tools are also good when you’re cutting at lower speeds or doing fine detail like threading and grooves. If you’re working on a custom job or a small batch, HSS gives you flexibility without needing special inserts.

These tools are often used in manual lathes, small shops, or when the job is one-of-a-kind. They may not last forever, but they can give you a nice finish and work well for many applications.

Ceramic and CBN Tools: Best for Hard Metals

If you need to cut very hard metals—like steel that’s been heat-treated—ceramic and CBN (cubic boron nitride) tools are your best choice. These tools stay hard even at very high temperatures, so they can cut tough materials without breaking down quickly.

CBN tools are great for finishing hard parts, especially when you need a smooth surface and tight tolerances. They’re strong, but also more expensive and can break if not used correctly—so it’s important to have a stable setup.

Ceramic tools are good for roughing harder metals like Inconel or Hastelloy. These are often used in parts for airplanes or medical devices. Ceramic tools can remove a lot of material quickly without needing to switch to a grinder.

Brazed Carbide Tools for Stability and Strength

Brazed carbide lathe tools consist of a solid carbide tip brazed to a steel shank. While not as flexible as indexable systems, they offer strong cutting edges and are often used in high-stability, high-rigidity setups.

These tools are a solid option when cutting cast iron, stainless steel, and other tough materials. They’re less common today but still preferred in some shops for their predictable performance and resistance to insert movement or loosening under load.

If you’re running older lathes or need a robust tool for roughing, brazed carbide tools can still deliver great results with proper care and sharpening.

Tips for Getting the Most from Your Lathe Tools

No matter what kind of cutting tools you use, how you take care of them matters just as much as which ones you choose. If your tools are set up the wrong way or not maintained properly, you can end up with bad finishes, damaged parts, or broken tools. Here are some smart, simple tips to make your tools last longer and work better:

Keep tools sharp

Even the best cutting tools don’t last forever. If an insert starts to chip, round off, or dull, it creates more heat and can leave a rough surface on your part. It also puts more pressure on your machine. Change dull tools before they slow you down.

Use the right tool for the job

Not every tool works for every material. Steel, aluminum, and brass all cut differently. Make sure you match the material you’re using turning tools with. Switching tools when needed helps your parts come out clean and protects your machine from wear.

Check tool position and overhang

If your tool is sticking out too far or not aligned correctly, it can shake while cutting. This can leave marks on your part and wear out the tool faster. Keep your tool setup tight and square.

Make sure the coolant is working

Coolant keeps your tool and part from overheating. It also helps wash away chips from the cutting area. Always check that your coolant is flowing correctly and isn’t low or dirty.

Inspect toolholders often

Even if your insert is brand new, it won’t work well in a damaged or dirty holder. Clean your holders regularly and replace them if they’re bent, cracked, or full of burrs. A solid toolholder keeps your insert stable and accurate.

Tool Brands Trusted by Professionals

There are many brands that make great lathe cutting tools. Some shops prefer one brand over another, but here are a few names that come up again and again when precision and reliability matter:

- Sandvik Coromant – A top name in carbide inserts and modular tool systems, especially for big production jobs.

- Kennametal – Known for strong tools that work on many types of metal.

- Iscar – Great for high-speed turning and controlling chip flow.

- Accusize and Micro 100 – Budget-friendly options with solid performance for small and mid-sized shops.

- Tungaloy – Excellent for threading and detailed finish cuts with clean results.

Choose a brand that fits your budget and the materials you work with most often. It also helps to use systems that support quick tool changes or preset holders, so you can save time on setup and get better results across every job.

Set Up for Long-Term Success

The best metal lathe cutting tools are the ones that match your machine, your parts, and your goals. Carbide inserts work great for tough metals and fast production. HSS tools are helpful for custom jobs or softer materials. And ceramic or CBN tools are perfect when you’re turning hard parts that need extra precision.

No matter what kind of parts you make, using the right tool can improve your finish, cut down on waste, and keep your machine running at its best.

Need help choosing the right tooling or setting up a better turning process? In-House CNC can help you improve performance with expert advice and support.

Contact us today at (951) 540-4820 to talk with a specialist—we’ll help you find the best tools to boost accuracy, reduce downtime, and keep your shop moving.