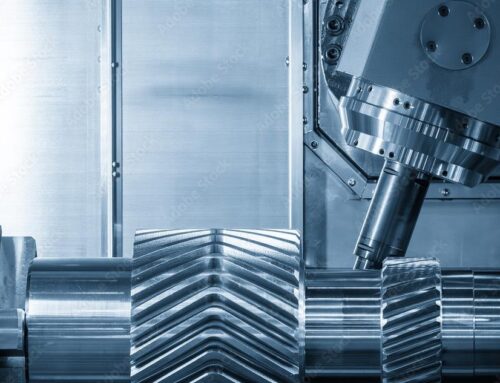

Examples of Intricate Components Made with CNC Machining

Share Post

Examples of Intricate Components Made with CNC Machining

CNC (Computer Numerical Control) machining has changed the way industries make small, detailed, and highly accurate parts. Instead of using hand-operated tools, CNC machines follow computer instructions to cut, shape, and form materials with extreme precision.

Many industries, like aerospace, medicine, automotive, and electronics, rely on CNC machining because it creates high-quality parts with exact measurements. Older methods required workers to shape intricate parts by hand, which could lead to mistakes.

CNC machining can produce every part that comes out the same, ensuring consistency and reliability. As technology improves, CNC machining continues to push the limits of what manufacturers can create.

The demand for complex geometries, precise parts and components are increasing, and CNC machines are leading the way.

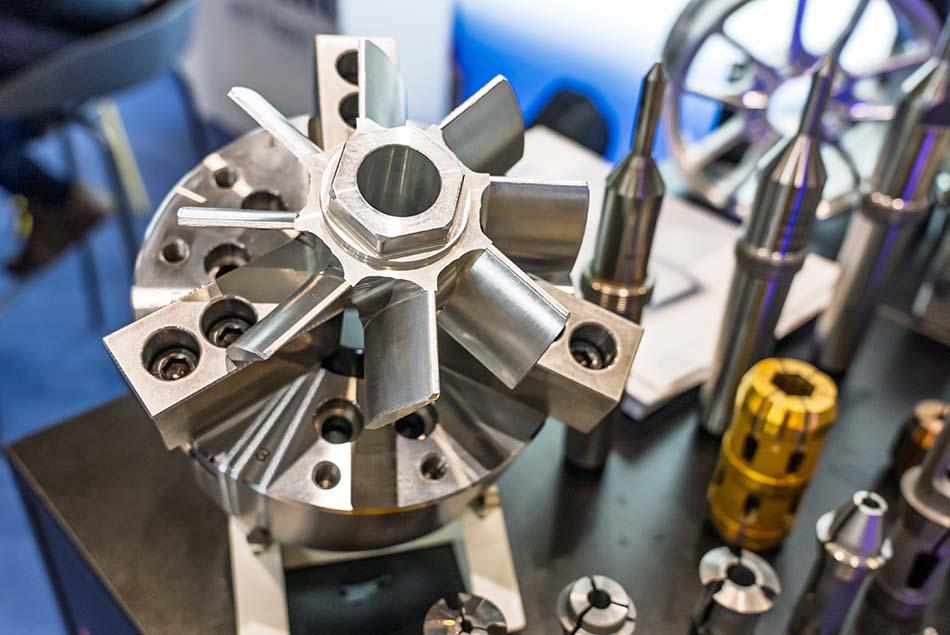

Below are some of the most detailed and impressive components that CNC machining helps manufacture today.

Industries That Use CNC Machining

CNC machining is a process that helps create strong, precise, and high-quality parts for many industries. It allows machines to cut, drill, and shape materials with extreme precision and accuracy, making it essential for everything from airplanes to jewelry.

Aerospace Parts

Airplanes and spacecraft need parts that are both lightweight and strong. These parts must handle high speeds, intense heat, and sudden pressure changes. Even a tiny mistake can be dangerous, so CNC machining ensures every piece is made exactly right.

One of the most important aerospace parts is the turbine blade, which helps jet engines run smoothly. These blades must be shaped perfectly to allow proper airflow and resist extreme heat. The frames and body parts of airplanes are also made using CNC machine works. Since planes need to be light but strong, materials like aluminum and titanium are used. In space travel, satellite and spacecraft parts must survive extreme temperatures and weightlessness, so CNC machining is used to make sure they are durable and precise.

Medical Equipment

Medical tools and implants must be made with extreme accuracy because they are used on or inside the human body. CNC machining helps doctors and surgeons by making high-quality medical equipment.

Surgical instruments, like scalpels, forceps, and clamps, must have smooth edges so they don’t cause harm during surgery. Bone implants and prosthetics need to fit a patient’s body perfectly, which CNC machining allows by creating custom-made joints, plates, and artificial limbs. In labs, testing devices with tiny pathways need precise machining to ensure they work correctly when diagnosing diseases.

Automotive and Racing Parts

Cars, especially race cars, need strong and reliable parts to perform well. CNC machining is used to create these parts with high precision. Engines and cylinder heads are two of the most important parts in a car, and they must be perfectly shaped to allow the right amount of fuel and air to flow. If these parts aren’t precise, the car won’t run efficiently.

Suspension parts are also machined to help cars handle turns smoothly and stay stable on the road. In racing, teams use CNC machining to create custom aerodynamic parts, allowing race cars to go faster while staying safe.

Electronics and Technology

Electronic devices have tiny, detailed parts that need to be made with extreme accuracy. CNC machining is used to create parts for computers, phones, and other technology.

Heat sinks are important because they keep devices from overheating. These metal parts must be cut precisely so they fit correctly and allow heat to escape. Circuit board housings protect delicate electronic parts from dust and damage. Since devices are getting smaller and more powerful, CNC machining is necessary to make sure these parts fit perfectly.

Defense and Firearms

The military and law enforcement need strong, reliable equipment, and CNC machining helps make parts that work perfectly every time.

Firearm parts, such as barrels, triggers, and gun slides, must be made with extreme precision. If even one part is slightly off, the weapon may not fire correctly. Military vehicle parts must be able to survive harsh conditions, like rough terrain and extreme weather. CNC machining ensures these parts are strong and long-lasting. The military also uses CNC machining for protective casings that shield important electronics from dust, water, and damage.

Robotics and Automation

Robots need highly precise parts to move smoothly and work properly. CNC machining helps make sure these machines function without any errors.

Robot arms and joints must be machined accurately so they move correctly and don’t get stuck. If a part is even slightly off, the robot won’t work properly. Gears and motors that control movement also need to fit together perfectly to keep robots running smoothly. Many robots use sensors to detect objects and surroundings, and CNC machining creates protective cases to keep these sensors safe.

Custom Jewelry and Engraving

CNC machining isn’t just used for machines and vehicles—it’s also used for making detailed jewelry and engravings.

Jewelers use CNC machining to create custom rings, necklaces, and bracelets with unique designs. The precision of CNC machines allows for tiny, detailed patterns that would be difficult to make by hand. Engraving businesses also use CNC machines to carve names, images, and designs onto metal, wood, and acrylic surfaces. These engravings are often used for personalized gifts, trophies, and branding.

The Future of Precision Manufacturing with CNC Machining

CNC machining has changed the way industries make small, detailed parts. It allows manufacturers to create intricate designs with incredible accuracy. From airplanes to medical devices, robots to luxury watches, complex CNC machining plays a crucial role in industries that need precision and reliability.

With better cutting tools and improved manufacturing processes, CNC machining continues to get better. New surface finishing techniques make sure that CNC-machined parts not only work well but also look smooth and polished. This level of detail sets a new standard for quality, allowing manufacturers to produce complex parts that meet high industry standards.

As technology advances, CNC machining will become even more precise, faster, and more efficient. Automation, artificial intelligence, and new materials will help push CNC machining to new levels. CNC milling machines and other controlled machines will allow manufacturers to create even more intricate designs while saving time and materials. The future of CNC machining is bright, and it will continue to be one of the most important tools in modern manufacturing.