Understanding Tolerances in CNC Machining

2 items

Menu

Services

Emergency Contact Form

Newsletter Signup!

© All rights reserved. • In-House CNC Service LLC | Privacy Policy | Terms of Service • Web Design Services In ABQ by Design it Right

2 items

© All rights reserved. • In-House CNC Service LLC | Privacy Policy | Terms of Service • Web Design Services In ABQ by Design it Right

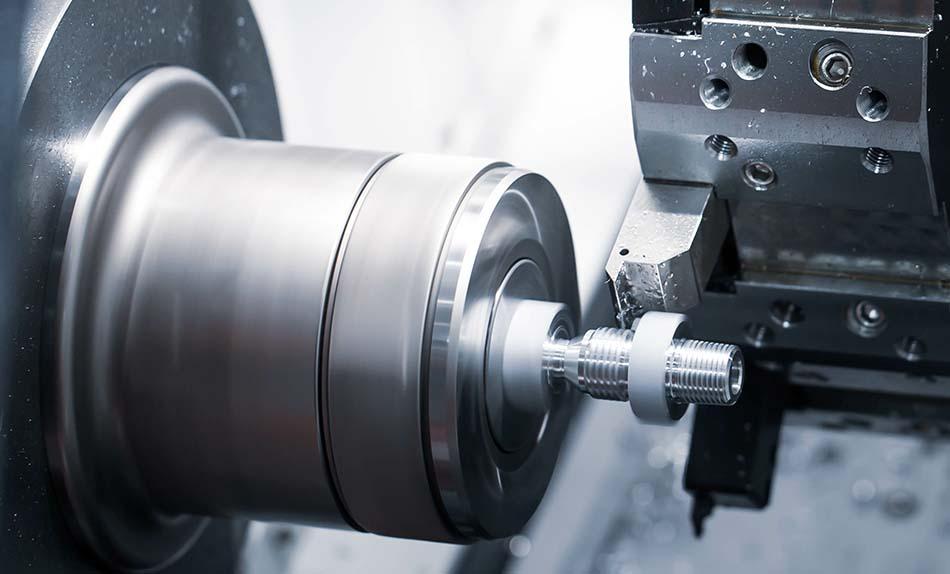

Precise tolerances are crucial in CNC machining, as they directly impact the quality, functionality, and cost-effectiveness of the final product. Tighter tolerances ensure a higher degree of accuracy and consistency, which is essential for many industrial applications.

By understanding the impact of tolerances, manufacturers can optimize their processes, reduce waste, and deliver parts that meet the exact specifications required by their customers. This knowledge helps In-House CNC Service provide reliable and cost-effective CNC machining services to its clients.

The required tolerances in CNC machining can vary depending on the specific application, the materials used, and the complexity of the part design. Factors such as the intended use of the part, the level of precision needed, and the cost constraints all play a role in determining the appropriate tolerance levels.

Manufacturers must carefully consider these factors to strike a balance between cost, quality, and performance. In-House CNC Service works closely with its clients to understand their unique requirements and recommend the optimal tolerance levels for their CNC machining projects.

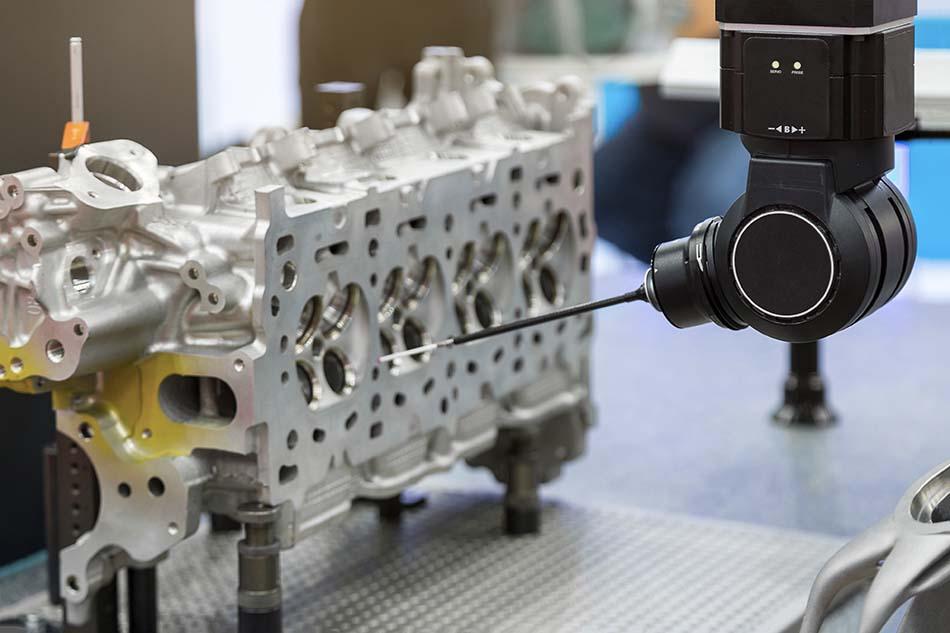

Advancements in CNC technology, tooling, and machine programming have enabled manufacturers to achieve increasingly tighter tolerances. Techniques such as precise tool path planning, advanced tool compensation, and real-time monitoring and adjustment can help ensure consistent and accurate results.

In-House CNC Service leverages these state-of-the-art CNC machining capabilities to deliver parts that meet the most stringent tolerance requirements. By continuously investing in the latest technology and training its skilled technicians, the company ensures its clients receive the highest quality CNC machining services.

Effective communication and education are crucial in helping clients understand the importance of tolerances in CNC machining. In-House CNC Service actively engages with its clients, providing them with resources and guidance on how to optimize their part designs and tolerance requirements.

By sharing its expertise and collaborating with clients, the company ensures that they make informed decisions and achieve the best possible outcomes for their CNC machining projects. This approach helps build long-term partnerships and fosters a deeper understanding of the complexities involved in precision manufacturing.