CNC Milling vs. CNC Turning

2 items

Menu

Services

Emergency Contact Form

Newsletter Signup!

© All rights reserved. • In-House CNC Service LLC | Privacy Policy | Terms of Service • Web Design Services In ABQ by Design it Right

2 items

© All rights reserved. • In-House CNC Service LLC | Privacy Policy | Terms of Service • Web Design Services In ABQ by Design it Right

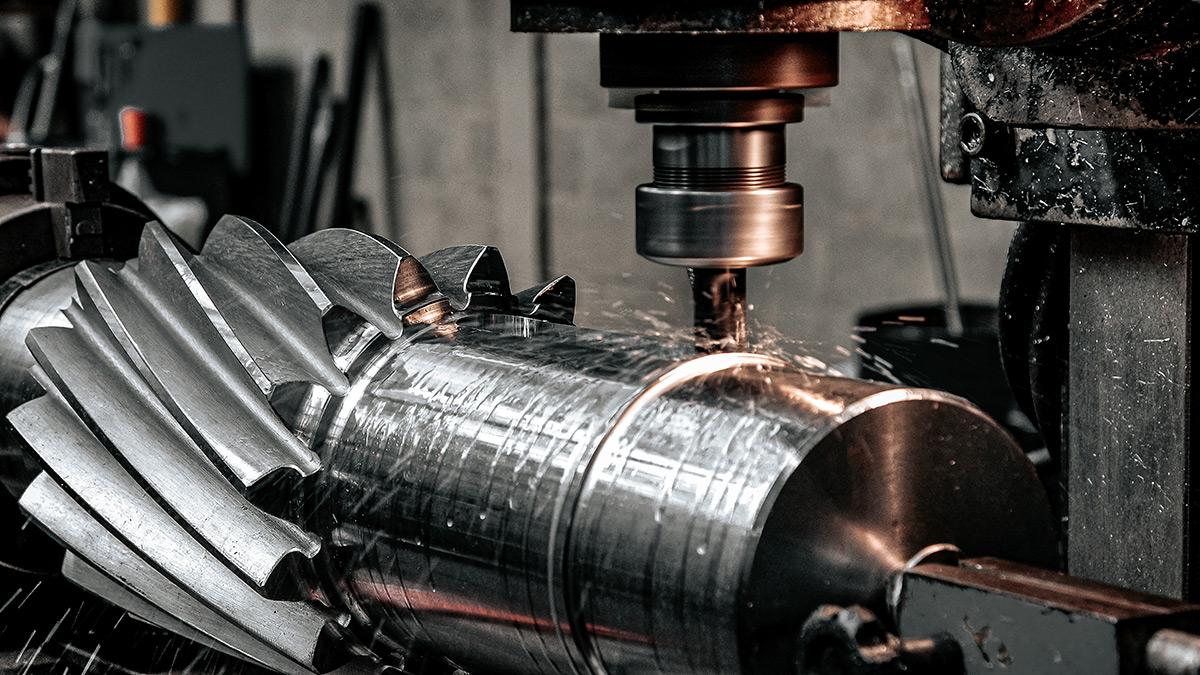

CNC milling is a versatile machining process that uses a computer-controlled rotating tool to remove material from a workpiece. It is commonly used for creating complex, three-dimensional parts with high precision and accuracy.

CNC milling offers a range of benefits, such as the ability to produce intricate designs, tight tolerances, and smooth surface finishes. It is widely used in industries like aerospace, automotive, and medical device manufacturing.

CNC turning is a machining process that uses a computer-controlled lathe to create parts by rotating a workpiece against a cutting tool. It is particularly well-suited for producing cylindrical or axisymmetric components.

The key advantages of CNC turning include high-speed production, improved dimensional accuracy, and cost-effectiveness for large-volume manufacturing. It is commonly used in the production of shafts, bushings, and other rotational parts.

By integrating CNC milling and turning capabilities, manufacturers can create complex parts that would be difficult or impossible to produce using a single machining process. This combination allows for the efficient and precise fabrication of components with both rotational and non-rotational features.

Integrating CNC milling and turning can lead to time and cost savings, as well as increased flexibility in the manufacturing process. It is particularly beneficial for the production of parts with intricate geometries or mixed features.

The choice between CNC milling and CNC turning depends on the specific requirements of the part being produced, such as its shape, size, and features. Factors like production volume, material, and tolerances should also be considered when selecting the appropriate machining process.

In-House CNC Service can provide guidance and expertise to help customers determine the most suitable CNC machining solution for their manufacturing needs, ensuring efficient and high-quality results.