CNC Machine Maintenance and Repair Services

In-House CNC Service LLC specializes in providing comprehensive maintenance and repair services for CNC machines. Our team of experienced technicians can diagnose and address a wide range of issues, ensuring your CNC equipment operates at peak performance.

From routine preventative maintenance to emergency repairs, we offer tailored solutions to keep your CNC machines running smoothly. Our services cover everything from component replacement and software updates to custom modifications and upgrades, all to enhance the efficiency and longevity of your CNC technology.

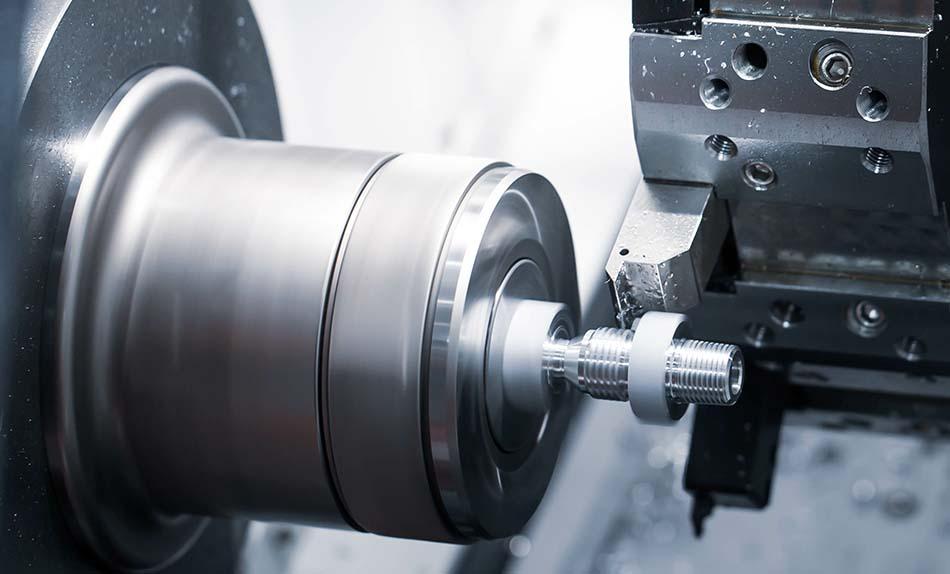

Advantages of CNC Machining

CNC machining offers numerous benefits for small-batch production, including enhanced precision, consistency, and cost-effectiveness. Our experts can help you leverage the advantages of CNC technology to optimize your manufacturing processes and achieve superior results.

By understanding the unique capabilities and limitations of CNC machining, we can guide you in designing parts and components that maximize efficiency, minimize waste, and deliver high-quality outcomes. Our insights can help you overcome challenges and unlock the full potential of CNC technology.

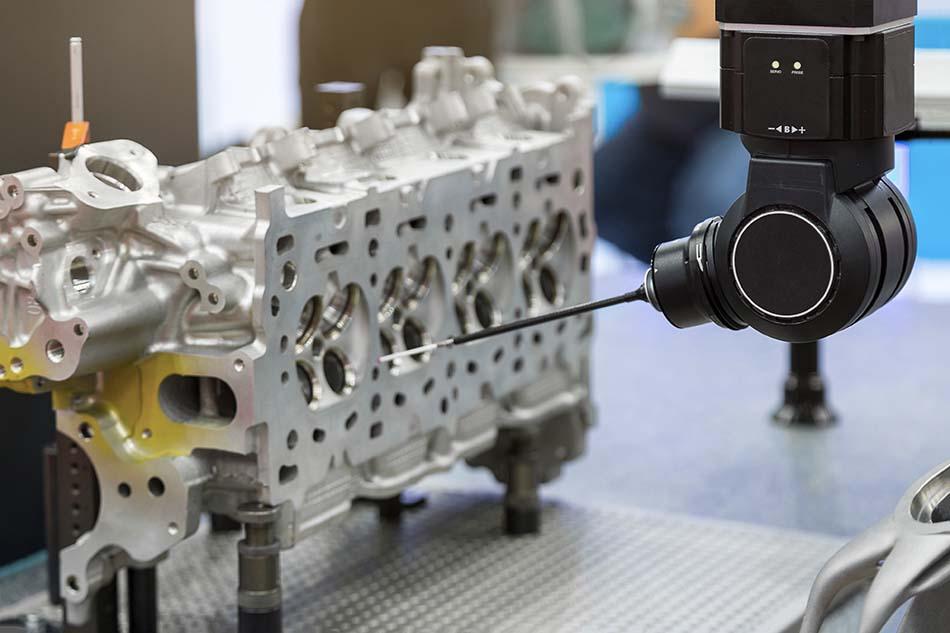

Precision and Tolerances in CNC Machining

Maintaining tight tolerances is crucial in CNC machining to ensure the accuracy and reliability of your parts. Our team can help you navigate the complexities of tolerance management, providing guidance on how to balance manufacturing costs with the required level of precision.

By understanding the factors that influence tolerances, such as tool selection, machine capabilities, and material properties, we can help you optimize your CNC processes and consistently produce parts that meet or exceed your quality standards.

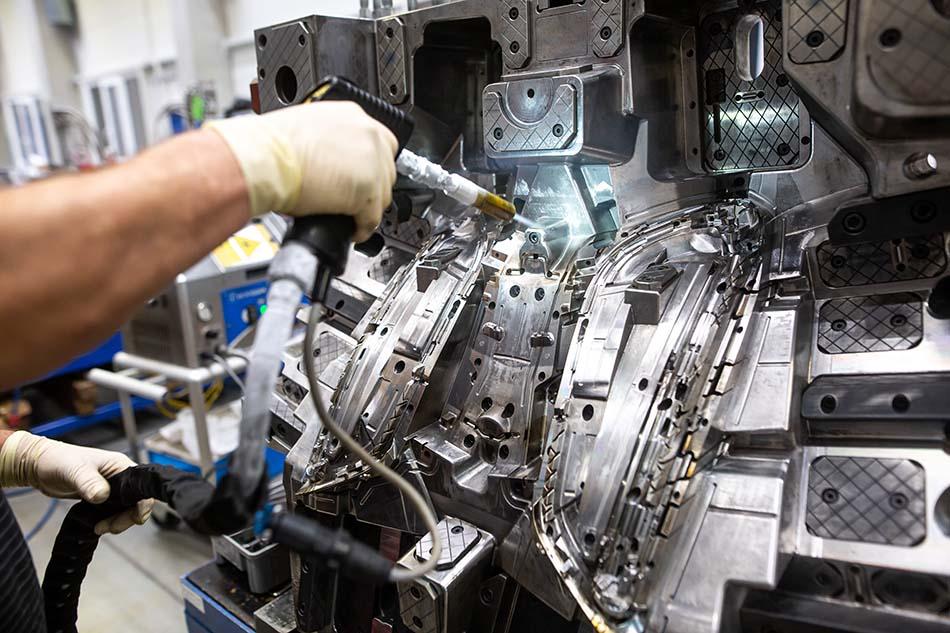

Tooling and Fixturing in CNC Machining

The selection and use of appropriate tools and fixtures play a critical role in the efficiency and quality of CNC machining. Our experts can advise you on the best tooling and fixturing solutions to enhance your CNC operations, considering factors like machining speed, surface finish, and part complexity.

From cutting tools and workholding devices to automation systems and specialty fixtures, we can help you implement the optimal tooling strategies to boost productivity, reduce downtime, and deliver superior results in your CNC manufacturing processes.