Jason Wutzke: CNC Service Specialist

91 items

Menu

Services

Emergency Contact Form

Newsletter Signup!

© All rights reserved. • In-House CNC Service LLC | Privacy Policy | Terms of Service • Web Design Services In ABQ by Design it Right

91 items

© All rights reserved. • In-House CNC Service LLC | Privacy Policy | Terms of Service • Web Design Services In ABQ by Design it Right

house maintenance

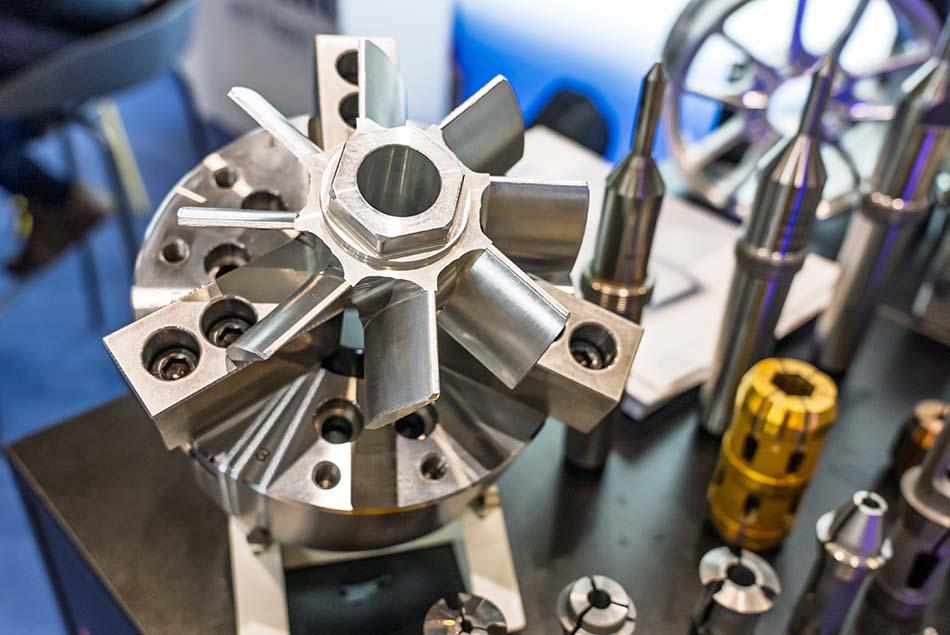

This section focuses on providing comprehensive guides and resources for maintaining and repairing CNC machines. It addresses common issues, best practices, and expert-level insights to help clients minimize downtime and optimize the performance of their CNC equipment.

Featured topics include spindle repair, troubleshooting common malfunctions, and implementing preventative maintenance strategies to extend the lifespan of CNC machines. Clients can find step-by-step instructions, diagrams, and expert recommendations to effectively maintain their CNC machinery.

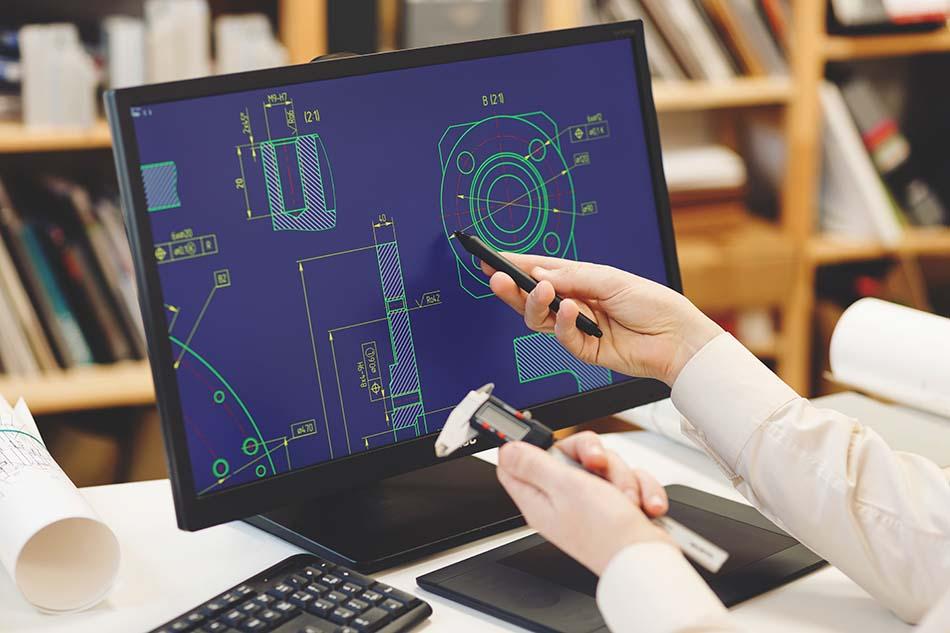

This section explores the role of CAD/CAM software in streamlining CNC machining processes. It highlights how the integration of design and manufacturing tools can lead to reduced lead times, improved accuracy, and increased efficiency for complex CNC projects.

Readers will learn about the benefits of CAD/CAM integration, such as automated toolpath generation, reduced programming errors, and enhanced part visualization. The content also provides guidance on selecting the right CAD/CAM software and effectively implementing it within CNC workflows.

This section focuses on the environmental impact of CNC machining and outlines sustainable manufacturing practices to minimize waste and improve efficiency. It addresses the importance of adopting eco-friendly CNC techniques and technologies to support the growing demand for environmentally conscious production.

Readers will discover strategies for reducing material consumption, optimizing energy usage, and implementing closed-loop recycling systems. The content also highlights how CNC machining can contribute to sustainable manufacturing and how businesses can leverage these practices to stay competitive in the market.

This section provides a comparative analysis of CNC machining and 3D printing, helping readers understand the strengths and limitations of each technology. It guides clients in selecting the most appropriate manufacturing process based on their specific project requirements, part complexity, and production needs.

The content covers factors such as part accuracy, material selection, lead times, and scalability to assist clients in making informed decisions. Readers will also learn about the unique applications and use cases for CNC machining and 3D printing, enabling them to leverage the right technology for their manufacturing requirements.