****

What is CNC Machining and How Can It Benefit Your Business?

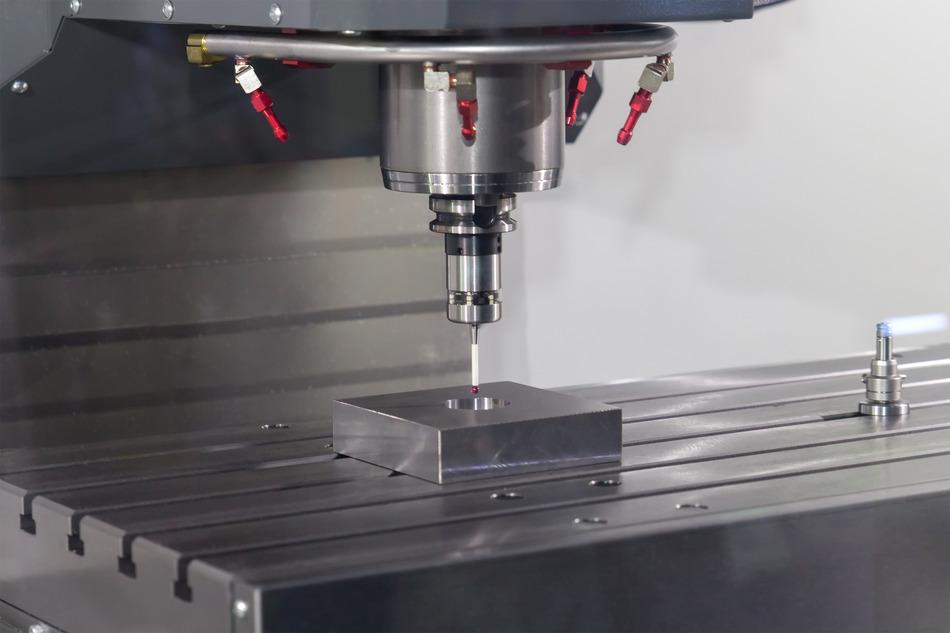

CNC (Computer Numerical Control) machining is a highly precise and efficient manufacturing process that uses computer-controlled machinery to create parts and components. By leveraging CNC technology, businesses can streamline their production, improve quality, and increase their competitiveness in the market.

CNC machining offers numerous benefits, including reduced production time, tighter tolerances, and the ability to create complex geometries. This technology can be particularly useful for businesses that require custom parts, small-batch production, or rapid prototyping.

Preventive Maintenance for CNC Machines

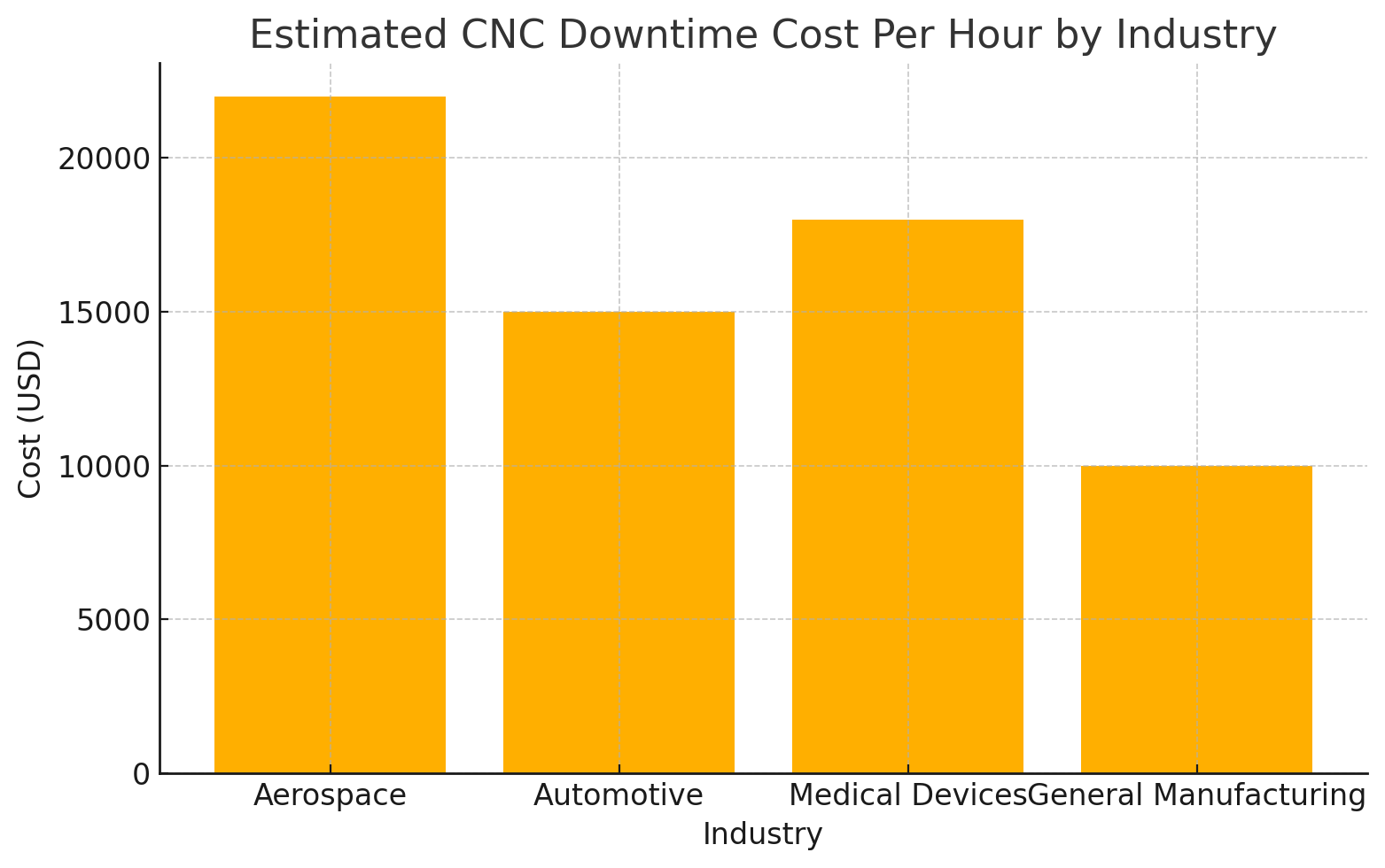

Regular preventive maintenance is crucial for ensuring the optimal performance and longevity of CNC machines. Proactive maintenance can help businesses avoid costly breakdowns, minimize downtime, and maintain consistent product quality.

Preventive maintenance tasks may include lubrication, calibration, cleaning, and replacement of worn parts. By following a comprehensive maintenance plan, businesses can extend the lifespan of their CNC machines and ensure they continue to operate at peak efficiency.

CNC Repair and Field Service

When CNC machines experience issues or malfunctions, prompt and reliable repair services are essential. Professional CNC repair technicians can diagnose and address a wide range of problems, from mechanical failures to software-related issues.

In-field service options can be particularly valuable for businesses that require immediate assistance or have CNC machines located at remote job sites. Skilled technicians can quickly assess the problem and provide on-site repairs, minimizing downtime and ensuring the continued productivity of the equipment.

Upgrading CNC Machines for Improved Performance

As technology advances, businesses may find that upgrading their CNC machines can lead to significant improvements in productivity, efficiency, and competitiveness. Upgrades may include the installation of newer software, the integration of advanced sensors and monitoring systems, or the replacement of aging components.

By investing in CNC machine upgrades, businesses can take advantage of the latest technological advancements, enhance their manufacturing capabilities, and stay ahead of the competition.