Skip to contentBallbar & Laser Calibration ServiceMike Jennings2025-02-28T02:43:23+00:00 machine, laser, accuracy and precision, machine tool, measurement, calibration, manufacturing, indicator, spindle, interferometry, frequency, traceability, quality, milling, rotation, wear and tear, ball screw, wear, screw, specification, customer, geometry, deviation, metrology, laboratory, downtime, quality management, machinist, cutting tool, perpendicular, laser tracker, backlash, calipers, scrap, customer satisfaction, six degrees of freedom, quality management system, degrees of freedom, motion, communication, certified reference materials, repeatability, sensor, vibration, humidity, productivity, numerical control, automation, machine shop, stainless steel, steel, aluminium, metal, engine, plastic, surface finish, anodizing, alloy, lathe, aerospace, carbon steel, polyoxymethylene, corrosion, titanium, polyether ether ketone, polytetrafluoroethylene, powder coating, copper, acrylonitrile butadiene styrene, thermoplastic, brass, polycarbonate, tool steel, plating, factory, polyethylene, electrical discharge machining, prototype, drill, polyvinyl chloride, nickel, polypropylene, zinc, insulator, rapid prototyping, alloy steel, friction, design for manufacturability, nylon, lead, invar, chromate conversion coating, machine services, cnc machined parts, cnc machining online, machining, online cnc machining, leading provider, request a quote, metal fabrication, polyetherimide, iron, epoxy, dimension, composite material, electronics, bead, black oxide, medical device, gear, bronze, chemical resistance, cast iron, fiberglass, sheet metal, retrofitting, ductility, toughness, coat, inconel, technical drawing, carbon, diameter, protolabs network, electric generator, burr, oil, polyethylene terephthalate, bearing, rotary table, pipe, fanuc, thermal expansion, abrasion, laser cutting, inventory, titanium alloys, wire, inspection, resin, iso 13485, environmental stress cracking, turning, absorption, fatigue, passivation, inch, aircraft, oxide, gold plating, chloride, north america, router, moisture, welding, engineering plastic, stiffness, vacuum, workpiece, length, tape measure, end mill, stepper motor, micrometer, cnc router, parameter, radius, granite, clockwise

Frequently Asked Questions

How do you calibrate your machine?

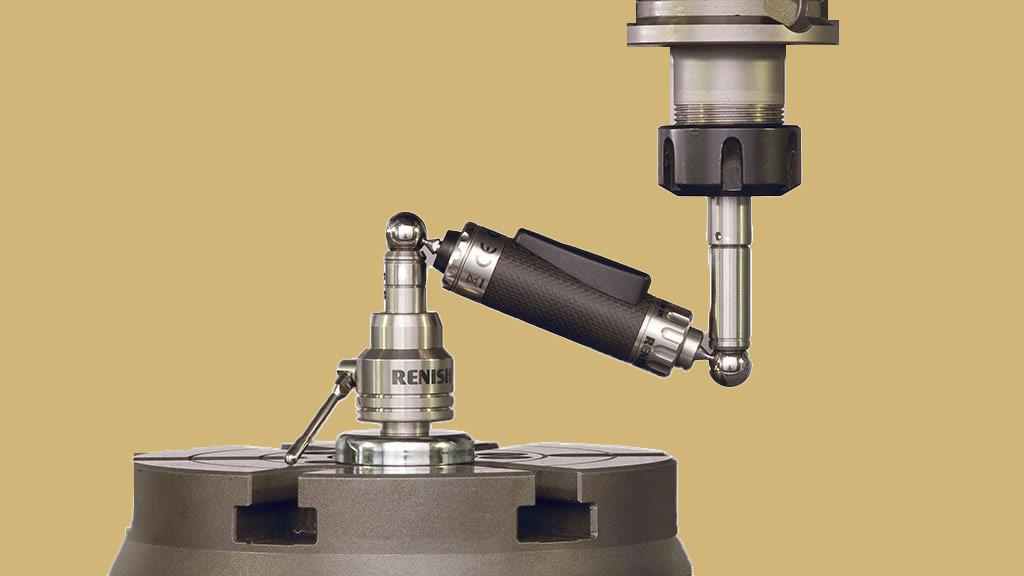

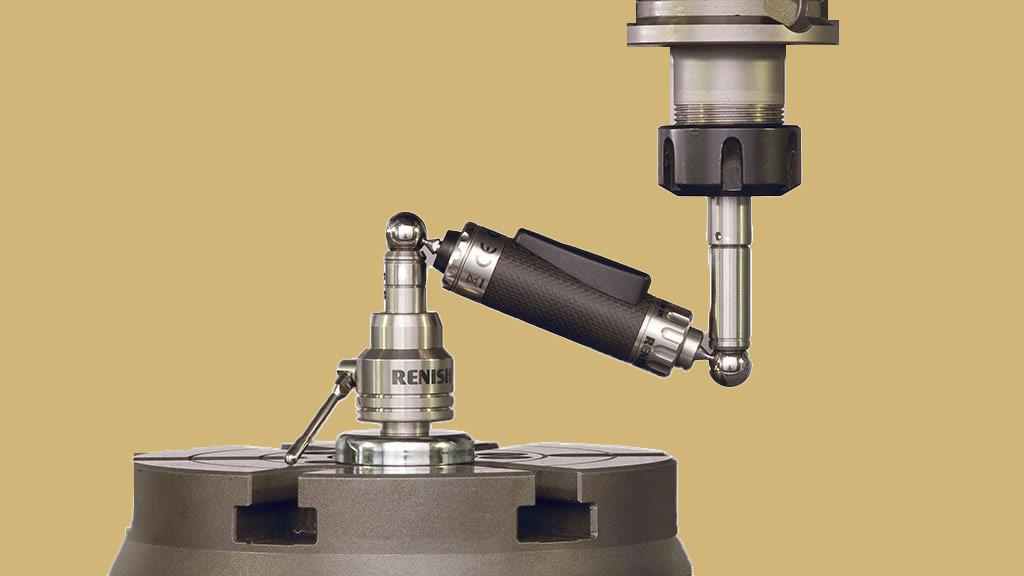

Calibrating a machine involves using precision tools like a ballbar or laser to measure and adjust the machine's accuracy and repeatability to industry standards.

How to calibrate a CNC machine?

Calibrating a CNC machine involves using specialized tools like ballbars and laser systems to measure and adjust the machine's accuracy, ensuring precise operations for optimal performance.

How to calibrate CNC router with Arduino?

Calibrating a CNC router with Arduino involves using the microcontroller to precisely control the movements and settings of the CNC machine, ensuring accurate and consistent cutting or engraving operations.

What tools are needed for CNC calibration?

The tools needed for CNC calibration typically include a ballbar, laser interferometer, and other specialized equipment to measure and verify the accuracy of the machine's motion and positioning.

How often should CNC machines be calibrated?

CNC machines should be calibrated regularly, typically every 3 to 6 months, to maintain optimal accuracy and performance. Proper calibration helps ensure precise part production and protects the long-term reliability of CNC equipment.

What are common CNC calibration issues?

Common CNC calibration issues include geometric errors, thermal errors, and wear and tear on machine components, which can lead to inaccurate part production. Proper calibration helps ensure optimal CNC machine performance and part quality.

Can you calibrate CNC machines remotely?

Yes, CNC machines can be calibrated remotely by our experienced technicians using specialized software and data analysis tools to ensure accurate and efficient calibration without the need for an on-site visit.

How to check CNC machine accuracy?

Checking the accuracy of a CNC machine involves performing a ballbar or laser calibration test. These tests measure the machine's positioning precision and identify any errors or deviations, allowing for necessary adjustments to optimize performance.

What factors affect CNC machine calibration?

Factors that affect CNC machine calibration include machine geometry, thermal effects, cutting forces, tool wear, and environmental conditions. Proper calibration ensures optimal machine performance and part accuracy.

What is the cost of CNC calibration services?

The cost of CNC calibration services varies depending on the scope of work, equipment, and complexity of the calibration process. Factors such as the number of axes, use of ballbar or laser systems, and travel distance can affect the pricing.

How to calibrate laser alignment in CNC?

Calibrating laser alignment in CNC involves adjusting the laser beam to ensure precise positioning and movement of the cutting tool relative to the workpiece, improving the overall accuracy and quality of CNC operations.

What is laser calibration for CNC machines?

Laser calibration for CNC machines is a precise method to measure and adjust the accuracy of machine tool axes and movements, ensuring optimal performance and part quality.

How do you troubleshoot calibration failures?

Troubleshooting calibration failures involves identifying the root cause, such as incorrect machine setup, worn components, or environmental factors, and taking corrective actions to ensure accurate CNC machine calibration.

How to maintain CNC machine calibration?

Maintaining CNC machine calibration involves regular ballbar and laser calibration to ensure precise machine operations and optimal performance. This helps identify and address any mechanical issues or alignment problems to maintain consistent accuracy.

What are benefits of CNC machine calibration?

The benefits of CNC machine calibration include improved accuracy, repeatability, and production efficiency, leading to higher-quality parts and reduced scrap, downtime, and maintenance costs for CNC operations.

Can you calibrate CNC machines without a technician?

Calibrating CNC machines without a technician can be challenging, as it requires specialized expertise and equipment. Proper calibration by a qualified technician is essential to ensure the accuracy and precision of CNC operations.

What specifications are needed for CNC calibration?

The specifications needed for CNC calibration include details about the CNC machine, such as its make, model, and axis configuration, as well as information about the workpiece materials, cutting tools, and desired tolerances for precise machining operations.

How to track CNC calibration history?

Tracking CNC calibration history involves maintaining detailed records of calibration dates, test results, and any adjustments made to the CNC equipment. This helps monitor performance, identify trends, and ensure consistent precision over time.

What software aids CNC machine calibration?

Software that aids CNC machine calibration includes specialized programs that analyze machine measurements and geometrical errors to help technicians align and optimize CNC equipment for precise operations.

How do environmental factors impact CNC calibration?

Environmental factors like temperature, humidity, and vibration can significantly impact the accuracy of CNC calibration. Precise calibration is essential to ensure optimal CNC machine performance and maintain manufacturing quality standards.

What is the process for CNC machine calibration?

The process for CNC machine calibration involves using precision measurement tools, such as a ballbar or laser, to assess the machine's accuracy and make necessary adjustments to ensure optimal performance.

How to ensure precise CNC machine functioning?

Ensuring precise CNC machine functioning involves regular calibration and maintenance. Ballbar and laser calibration services can help identify and address issues with machine accuracy, thereby optimizing CNC performance and productivity.

What industry standards apply to CNC calibration?

The industry standards that apply to CNC calibration include ISO 230 (Testing of Machine Tools), ASME B5.54 (Methods for Performance Evaluation of Computer Numerically Controlled Machining Centers), and VDI/DGQ 3441 (Statistical Testing of the Operational and Positional Accuracy of Machine Tools).

Is DIY CNC calibration recommended?

DIY CNC calibration is generally not recommended, as it requires specialized equipment and expertise to ensure accurate and reliable calibration of CNC machines. Professional calibration services are typically the best option for maintaining optimal CNC performance.

How do you calibrate spindle speed on CNC?

Calibrating the spindle speed on a CNC machine involves using a tachometer or other measuring device to verify the actual spindle speed matches the programmed speed, making adjustments as needed to ensure accuracy.

What steps ensure effective CNC calibration?

Effective CNC calibration involves meticulously measuring and adjusting machine parameters, such as axis positioning, spindle performance, and geometric alignment, to ensure optimal machine precision and productivity.

How to recalibrate CNC machines for new tools?

Recalibrating CNC machines for new tools involves adjusting the machine's settings and parameters to ensure accurate positioning and cutting, including verifying tool length offsets, updating tool data, and running test cuts.

What parameters should be monitored during calibration?

The key parameters that should be monitored during CNC calibration include backlash, straightness, squareness, and position accuracy of the machine's axes. Regularly monitoring these critical parameters ensures optimal performance and precision of the CNC equipment.

How to document CNC machine calibration results?

Documenting CNC machine calibration results involves recording the before and after measurements, the adjustments made, and the final calibration status to ensure accurate record-keeping and performance monitoring.

What is the role of calibration in CNC accuracy?

Calibration plays a crucial role in maintaining CNC accuracy by ensuring the machine's components, such as the axes, spindle, and tooling, are properly aligned and functioning within specified tolerances, enabling precise and consistent machining operations.

cnc machine laser calibration, cnc calibration services, cnc calibration, ballbar, cnc laser calibration, cnc calibration suppliers, cnc ballbar testing, machine tool laser calibration, ball bar calibration, ballbar calibration, ball bar testing services, in house cnc service

machine, laser, accuracy and precision, machine tool, measurement, calibration, manufacturing, indicator, spindle, interferometry, frequency, traceability, quality, milling, rotation, wear and tear, ball screw, wear, screw, specification, customer, geometry, deviation, metrology, laboratory, downtime, quality management, machinist, cutting tool, perpendicular, laser tracker, backlash, calipers, scrap, customer satisfaction, six degrees of freedom, quality management system, degrees of freedom, motion, communication, certified reference materials, repeatability, sensor, vibration, humidity, productivity, numerical control, automation, machine shop, stainless steel, steel, aluminium, metal, engine, plastic, surface finish, anodizing, alloy, lathe, aerospace, carbon steel, polyoxymethylene, corrosion, titanium, polyether ether ketone, polytetrafluoroethylene, powder coating, copper, acrylonitrile butadiene styrene, thermoplastic, brass, polycarbonate, tool steel, plating, factory, polyethylene, electrical discharge machining, prototype, drill, polyvinyl chloride, nickel, polypropylene, zinc, insulator, rapid prototyping, alloy steel, friction, design for manufacturability, nylon, lead, invar, chromate conversion coating, machine services, cnc machined parts, cnc machining online, machining, online cnc machining, leading provider, request a quote, metal fabrication, polyetherimide, iron, epoxy, dimension, composite material, electronics, bead, black oxide, medical device, gear, bronze, chemical resistance, cast iron, fiberglass, sheet metal, retrofitting, ductility, toughness, coat, inconel, technical drawing, carbon, diameter, protolabs network, electric generator, burr, oil, polyethylene terephthalate, bearing, rotary table, pipe, fanuc, thermal expansion, abrasion, laser cutting, inventory, titanium alloys, wire, inspection, resin, iso 13485, environmental stress cracking, turning, absorption, fatigue, passivation, inch, aircraft, oxide, gold plating, chloride, north america, router, moisture, welding, engineering plastic, stiffness, vacuum, workpiece, length, tape measure, end mill, stepper motor, micrometer, cnc router, parameter, radius, granite, clockwise

Frequently Asked Questions

How do you calibrate your machine?

Calibrating a machine involves using precision tools like a ballbar or laser to measure and adjust the machine's accuracy and repeatability to industry standards.

How to calibrate a CNC machine?

Calibrating a CNC machine involves using specialized tools like ballbars and laser systems to measure and adjust the machine's accuracy, ensuring precise operations for optimal performance.

How to calibrate CNC router with Arduino?

Calibrating a CNC router with Arduino involves using the microcontroller to precisely control the movements and settings of the CNC machine, ensuring accurate and consistent cutting or engraving operations.

What tools are needed for CNC calibration?

The tools needed for CNC calibration typically include a ballbar, laser interferometer, and other specialized equipment to measure and verify the accuracy of the machine's motion and positioning.

How often should CNC machines be calibrated?

CNC machines should be calibrated regularly, typically every 3 to 6 months, to maintain optimal accuracy and performance. Proper calibration helps ensure precise part production and protects the long-term reliability of CNC equipment.

What are common CNC calibration issues?

Common CNC calibration issues include geometric errors, thermal errors, and wear and tear on machine components, which can lead to inaccurate part production. Proper calibration helps ensure optimal CNC machine performance and part quality.

Can you calibrate CNC machines remotely?

Yes, CNC machines can be calibrated remotely by our experienced technicians using specialized software and data analysis tools to ensure accurate and efficient calibration without the need for an on-site visit.

How to check CNC machine accuracy?

Checking the accuracy of a CNC machine involves performing a ballbar or laser calibration test. These tests measure the machine's positioning precision and identify any errors or deviations, allowing for necessary adjustments to optimize performance.

What factors affect CNC machine calibration?

Factors that affect CNC machine calibration include machine geometry, thermal effects, cutting forces, tool wear, and environmental conditions. Proper calibration ensures optimal machine performance and part accuracy.

What is the cost of CNC calibration services?

The cost of CNC calibration services varies depending on the scope of work, equipment, and complexity of the calibration process. Factors such as the number of axes, use of ballbar or laser systems, and travel distance can affect the pricing.

How to calibrate laser alignment in CNC?

Calibrating laser alignment in CNC involves adjusting the laser beam to ensure precise positioning and movement of the cutting tool relative to the workpiece, improving the overall accuracy and quality of CNC operations.

What is laser calibration for CNC machines?

Laser calibration for CNC machines is a precise method to measure and adjust the accuracy of machine tool axes and movements, ensuring optimal performance and part quality.

How do you troubleshoot calibration failures?

Troubleshooting calibration failures involves identifying the root cause, such as incorrect machine setup, worn components, or environmental factors, and taking corrective actions to ensure accurate CNC machine calibration.

How to maintain CNC machine calibration?

Maintaining CNC machine calibration involves regular ballbar and laser calibration to ensure precise machine operations and optimal performance. This helps identify and address any mechanical issues or alignment problems to maintain consistent accuracy.

What are benefits of CNC machine calibration?

The benefits of CNC machine calibration include improved accuracy, repeatability, and production efficiency, leading to higher-quality parts and reduced scrap, downtime, and maintenance costs for CNC operations.

Can you calibrate CNC machines without a technician?

Calibrating CNC machines without a technician can be challenging, as it requires specialized expertise and equipment. Proper calibration by a qualified technician is essential to ensure the accuracy and precision of CNC operations.

What specifications are needed for CNC calibration?

The specifications needed for CNC calibration include details about the CNC machine, such as its make, model, and axis configuration, as well as information about the workpiece materials, cutting tools, and desired tolerances for precise machining operations.

How to track CNC calibration history?

Tracking CNC calibration history involves maintaining detailed records of calibration dates, test results, and any adjustments made to the CNC equipment. This helps monitor performance, identify trends, and ensure consistent precision over time.

What software aids CNC machine calibration?

Software that aids CNC machine calibration includes specialized programs that analyze machine measurements and geometrical errors to help technicians align and optimize CNC equipment for precise operations.

How do environmental factors impact CNC calibration?

Environmental factors like temperature, humidity, and vibration can significantly impact the accuracy of CNC calibration. Precise calibration is essential to ensure optimal CNC machine performance and maintain manufacturing quality standards.

What is the process for CNC machine calibration?

The process for CNC machine calibration involves using precision measurement tools, such as a ballbar or laser, to assess the machine's accuracy and make necessary adjustments to ensure optimal performance.

How to ensure precise CNC machine functioning?

Ensuring precise CNC machine functioning involves regular calibration and maintenance. Ballbar and laser calibration services can help identify and address issues with machine accuracy, thereby optimizing CNC performance and productivity.

What industry standards apply to CNC calibration?

The industry standards that apply to CNC calibration include ISO 230 (Testing of Machine Tools), ASME B5.54 (Methods for Performance Evaluation of Computer Numerically Controlled Machining Centers), and VDI/DGQ 3441 (Statistical Testing of the Operational and Positional Accuracy of Machine Tools).

Is DIY CNC calibration recommended?

DIY CNC calibration is generally not recommended, as it requires specialized equipment and expertise to ensure accurate and reliable calibration of CNC machines. Professional calibration services are typically the best option for maintaining optimal CNC performance.

How do you calibrate spindle speed on CNC?

Calibrating the spindle speed on a CNC machine involves using a tachometer or other measuring device to verify the actual spindle speed matches the programmed speed, making adjustments as needed to ensure accuracy.

What steps ensure effective CNC calibration?

Effective CNC calibration involves meticulously measuring and adjusting machine parameters, such as axis positioning, spindle performance, and geometric alignment, to ensure optimal machine precision and productivity.

How to recalibrate CNC machines for new tools?

Recalibrating CNC machines for new tools involves adjusting the machine's settings and parameters to ensure accurate positioning and cutting, including verifying tool length offsets, updating tool data, and running test cuts.

What parameters should be monitored during calibration?

The key parameters that should be monitored during CNC calibration include backlash, straightness, squareness, and position accuracy of the machine's axes. Regularly monitoring these critical parameters ensures optimal performance and precision of the CNC equipment.

How to document CNC machine calibration results?

Documenting CNC machine calibration results involves recording the before and after measurements, the adjustments made, and the final calibration status to ensure accurate record-keeping and performance monitoring.

What is the role of calibration in CNC accuracy?

Calibration plays a crucial role in maintaining CNC accuracy by ensuring the machine's components, such as the axes, spindle, and tooling, are properly aligned and functioning within specified tolerances, enabling precise and consistent machining operations.

cnc machine laser calibration, cnc calibration services, cnc calibration, ballbar, cnc laser calibration, cnc calibration suppliers, cnc ballbar testing, machine tool laser calibration, ball bar calibration, ballbar calibration, ball bar testing services, in house cnc service