Upgrading Your CNC Machine: Key Considerations and Benefits

Share Post

CNC machines have become indispensable tools in modern manufacturing, enabling businesses to achieve precision and efficiency. As technology evolves, however, older equipment may no longer meet the growing demands of production.

Upgrading your CNC machine can unlock new advantages—helping your business stay competitive and reduce costly inefficiencies.

Why Upgrade Your CNC Machine?

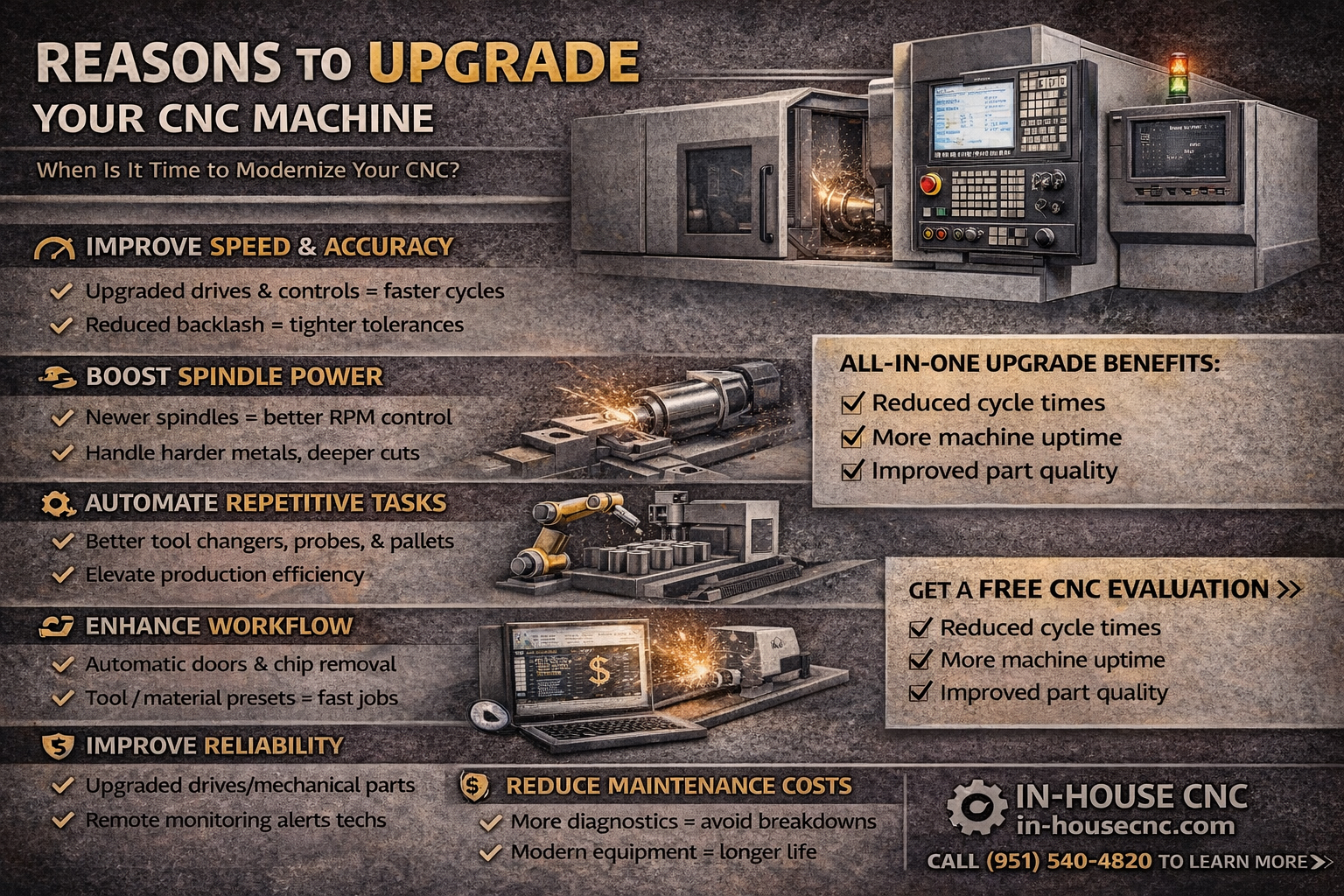

In this blog post, we’ll explore the many benefits of CNC upgrades, such as increased speed, improved accuracy, and expanded machining capabilities. A well-timed upgrade can improve productivity while extending the life of your equipment.

We’ll also cover what to consider before upgrading and share tips on choosing the right solutions for your shop’s unique needs—ensuring every investment supports your long-term goals.

Advantages of Upgrading CNC Machines:

By embracing upgrades, you can stay competitive and maximize the potential of your CNC machining operations.

Improved Efficiency: Upgrading your CNC machine can lead to significant improvements in efficiency. Advanced technologies, such as faster spindle speeds, enhanced tool changers, and improved control systems, reduces machine times and increases productivity.

Enhanced Precision and Quality: Upgraded CNC machines often feature advanced components and software that contribute to improved precision and higher quality output. Upgrades such as higher resolution encoders, improved feedback systems, and advanced control algorithms enable tighter tolerances and superior surface finishes. This enhances product quality and customer satisfaction.

Expanded capabilities: Upgrading your CNC machine can open up new possibilities by expanding its capabilities. For example, adding a fourth or fifth axis can enable complex multi-axis machining, allowing you to produce intricate parts with fewer setups. Integrating advanced probing systems can automate tool and workpiece measurement, streamlining processes and ensuring accuracy.

Compatibility with new technologies: Upgrading your CNC machine ensures compatibility with the latest technologies and software advancements. This allows you to leverage innovations such as cloud-based data management, machine learning algorithms for process optimization, and connectivity with Industry 4.0 systems. Staying up to date with technology trends enables you to embrace automation, streamline operations, and achieve greater efficiency.

Key Considerations for Upgrading:

It’s crucial to carefully consider various factors that will ensure a seamless transition and maximize the benefits of the new enhancements.

Evaluate your needs: Assess your current CNC machine’s limitations and identify the specific areas where an upgrade would provide the most significant benefits. Consider factors such as production volume, part complexity, desired precision, and available budget. Prioritize upgrades that address your immediate pain points and align with your long-term goals.

Research available upgrades: Conduct thorough research on the available upgrades for your CNC machine model. Consult with manufacturers, attend trade shows, and explore reputable online resources to gather information. Look for upgrades that directly address your identified needs and offer proven benefits in terms of efficiency, precision, or expanded capabilities.

Compatibility and integration: Ensure that the upgrades you consider are compatible with your existing CNC machine and can be seamlessly integrated. Consider factors such as mechanical fit, electrical compatibility, and software requirements. Compatibility issues can lead to additional expenses and complications during installation and operation.

Cost-effectiveness: Evaluate the cost-effectiveness of the upgrades by considering the potential return on investment (ROI). Compare the upfront costs with the projected savings or revenue gains resulting from the upgrade. Factors such as increased production capacity, reduced scrap rates, and improved customer satisfaction should be considered when assessing ROI.

Selecting the Right Upgrades:

Consult with experts:Seek advice from CNC machine experts, manufacturers, or industry professionals to get insights into the best upgrades for your specific needs. They can provide recommendations based on their expertise and experience, helping you make informed decisions.

Consider scalability: If you anticipate future growth or changing requirements, choose upgrades that allow for scalability. Opt for modular upgrades or those that can be expanded or modified in the future to accommodate evolving needs.

Training and support: Ensure that the manufacturer or supplier offers training and support for the upgraded CNC machine. Adequate training ensures that your operators are well-equipped to utilize the new features and capabilities effectively. Additionally, reliable support from the manufacturer can be invaluable in addressing any issues or questions that may arise during the transition and beyond.

User feedback and reviews: Take into account user feedback and reviews of the upgrades you are considering. This can provide valuable insights into the performance, reliability, and user experience of the upgraded CNC machines. Look for upgrades with positive reviews and testimonials from other users in similar industries or applications.

Consider The Following

Upgrading your CNC equipment doesn’t have to mean buying new machines. Retrofitting with modern components and software can dramatically improve output, precision, and uptime. Our retrofitting and upgrade solutions are designed to bring aging equipment up to today’s standards—without the high cost of replacement.